How a miniature USB vision module improved handling accuracy and reduced cycle time in a Silicon Valley robotics deployment

In today’s competitive robotics industry, especially in Silicon Valley’s fast-paced product development environment, precision grasping is no longer a “nice-to-have” — it is a core performance metric. For collaborative robots (Cobots) operating alongside human workers, vision systems must deliver high accuracy, low latency, and easy integration without adding weight or complexity to the robot arm.

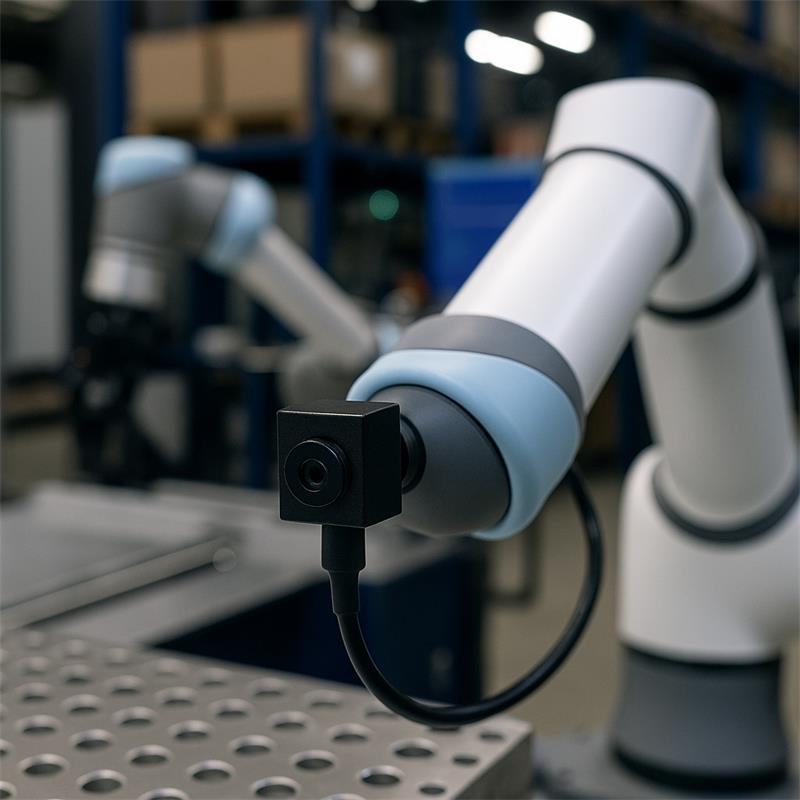

This case study examines how Brand X Robotics, a mid-sized robotics company headquartered in Mountain View, CA, successfully integrated the Novel 15×15 mm USB camera 2MP into its Cobot line to achieve significant gains in pick-and-place accuracy, cycle efficiency, and deployment speed. The project demonstrates how a micro USB camera for Cobot applications can meet the demanding requirements of Silicon Valley’s engineering culture.

Brand X Robotics specializes in lightweight, mobile Cobots used in electronics assembly and small-batch packaging. Their engineering team was tasked with designing a next-generation Cobot capable of:

The primary challenge was vision sensor selection. Previous attempts with off-the-shelf industrial cameras resulted in:

The team needed a miniature USB camera for Robots vision that would:

After a competitive evaluation, Brand X selected the Novel 15×15 mm USB camera 2MP — a compact vision module offering:

“From the first bench test, we realized the module could be mounted directly into our wrist shell without mechanical redesign,” said the lead mechanical engineer. “That shaved at least 3 weeks off our development schedule.”

The micro-size PCB allowed the camera to be mounted inline with the robot’s Z-axis, minimizing parallax errors. A custom 3D-printed bracket housed the lens flush with the Cobot’s wrist, protecting it from accidental contact.

Key Engineering Detail:

Because the module weighed under 8 g, it did not affect the Cobot’s dynamic payload calculation, allowing the original motion profiles to remain unchanged.

The USB interface allowed direct connection to the Cobot’s onboard Intel NUC-based control PC. No frame grabber or special drivers were needed — the system recognized the camera as a UVC device.

Software stack used:

Latency from frame capture to grasp command remained under 45 ms, meeting the real-time threshold for the pick-and-place loop.

The 2 MP resolution proved sufficient for detecting small mechanical components. The engineering team optimized:

A pilot unit was deployed in a contract manufacturing facility in Fremont, CA, assembling small electromechanical switches. The Cobot had to:

Performance improvements after integrating the Novel 15×15 mm USB camera 2MP:

|

Metric |

Before Integration |

After Integration |

Improvement |

|

Grasp success rate |

93.5% |

99.2% |

+5.7% |

|

Average cycle time |

3.4 s |

3.1 s |

–8.8% |

|

Integration time for new product lines |

3 weeks |

1 week |

–66% |

|

Camera maintenance downtime |

4 hrs/month |

<1 hr/month |

–75% |

Operator Feedback:

From this deployment, several lessons emerged for other Cobot manufacturers and integrators:

In Silicon Valley, speed of iteration is a competitive weapon. Hardware teams working in startup environments need components that are easy to integrate, require minimal NRE (non-recurring engineering), and scale from prototype to production without supply chain headaches.

A micro USB camera for Cobot use cases — such as the Novel 15×15 mm USB camera 2MP — embodies these principles:

Brand X Robotics’ integration of the Novel 15×15 mm USB camera 2MP is a prime example of how miniature USB camera for Robots vision technology can unlock measurable gains in precision grasping. By focusing on mechanical compatibility, ease of integration, and robust performance, the team achieved higher accuracy, faster cycles, and smoother deployment across customer sites.

In an industry where every millimeter and every millisecond counts, the choice of vision hardware can make the difference between a good Cobot and a market-leading one.

Call to Action:

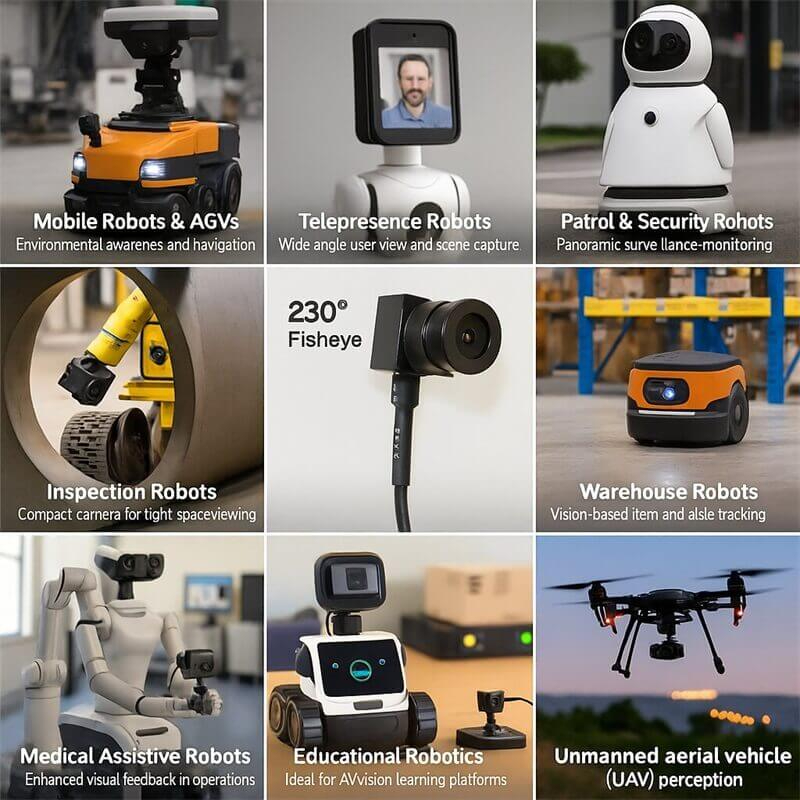

If you’re developing Cobots or robotic arms and need a robots sensor camera that combines compact design, industrial durability, and easy integration, contact Shenzhen Novel Electronics Limited. We offer customizable micro-camera solutions tailored to your vision application — from prototyping to mass production.

Relative Articles and 15*15mm Micro USB camera products links

1, 15*15mm USB Camera Success: Detroit, Chicago & US Case Study UC-501

2, 15*15mm Micro USB Camera apply for USA EU Robotics Vision UC-501

3, 15*15mm UC-501 USB camera for Robots

4, 15*15mm compact 8MP AF USB camera imx179 for Embedded Vision

5, NOVEL Technical white paper of micro usb camera with WDR UC-501-WDR

6, Why Robots Need Micro WDR USB Cameras UC-501-WDR?

7, NOVEL Custom Micro USB Cameras for AMR & Cobots USA & EU UC-501

8. 230°Fisheye USB-C embedded Camera 2MP 15x15mm for Robots (15*15mm miniature UVC camera for Robots version)