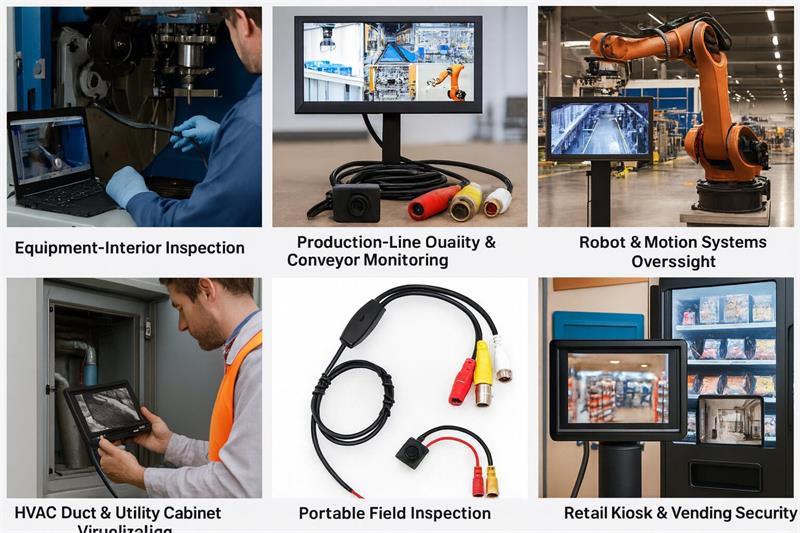

Industrial vision has two competing constraints: space and latency. On robot end-effectors, in control cabinets, along conveyors, or inside wind-turbine nacelles, there’s rarely room for a conventional camera, and there’s even less tolerance for network delays. The AC-606K solves both problems by pairing a 6×6 mm mini AHD camera with a 7-inch AHD monitor, delivering uncompressed 1080P over standard coax with near-zero delay. For teams comparing AHD vs IP camera architectures in 2024–2025, this compact analog HD approach is often the cleanest way to achieve real-time visibility with simple wiring and EMI-robust signaling.

This architecture removes IP addressing, switch provisioning, codec latency, and firmware dependencies. For portable inspection kit workflows, “camera → coax → 7″ monitor” is plug-and-play.

Recent searches for “AHD vs IP camera”, “long-distance video camera over coax”, and “EMI-resistant camera” trend upward in manufacturing and energy segments because plants face:

Problem: A robotized assembly cell needed visual confirmation of clip-fit quality inside a constrained fascia cavity. IP cameras added ~120–200 ms latency and required switch ports in an already crowded cabinet.

Solution: The 6×6 mm mini AHD camera was embedded directly into the end-effector shroud. A single 75 Ω coax routed through the robot dress-pack to an AHD monitor outside the cell.

Result: Technicians gained instant 1080P visibility during teach mode and live operation. Alignment time per changeover dropped 18%. No network config, no packet loss during welding operations.

Keywords used naturally: 1080p AHD camera kit, compact analog HD, industrial surveillance module.

Problem: Operators needed wide-area situational awareness of roller/belt transitions over 250 m of cable trays with high EMI from arc furnaces.

Solution: Deployed multiple 120-degree wide angle cameras (AHD) targeting choke points and return rollers; signals combined at an AHD DVR with quad-view to the control desk.

Result: Stable feeds with no blackouts during furnace current spikes. Two early roller misalignment events were detected in shift, preventing an estimated €40k in belt damage.

Keywords: 120 degree wide angle camera, long-distance video camera, embedded CCTV.

Problem: Case-packer changeovers suffered from inconsistent label alignment. Engineers needed “eyes on” the labeler throat without redesigning guards or adding switchgear.

Solution: Integrated the AC-606K with a 7-inch AHD monitor mounted on the machine frame. The discreet security camera view allowed real-time fine-tuning while the machine cycled at reduced speed.

Result: First-article acceptance improved by 21%; changeover time cut by 12 minutes on average. The EMI-resistant camera kept a stable picture near three VFDs and a servo amplifier.

Keywords: discreet security camera, 7-inch AHD monitor, EMI-resistant camera.

Problem: Remote substations required continuous visual checks inside control cabinets where Ethernet runs were prohibited and RF interference was pronounced.

Solution: The industrial surveillance module was panel-mounted behind a polycarbonate window with long-distance video over coax back to the relay room.

Result: During a breaker-trip investigation, engineers confirmed relay flag positions without opening the energized cabinet. The AHD link showed zero video drop during switching transients.

Keywords: industrial surveillance module, embedded CCTV, long-distance video camera.

Problem: Field teams needed a portable inspection kit to document weld root pass quality inside 2–3″ pipes without hauling NVRs or configuring mobile routers.

Solution: A handheld kit using the 6×6 mm AHD camera + 7″ monitor + battery pack. Footage was recorded via a compact AHD DVR for client sign-off.

Result: Turnaround per weld location dropped from ~40 to 25 minutes. Crews liked the plug-and-play workflow and real-time focus feedback for borescope-style positioning.

Keywords: portable inspection kit, long-distance analog HD, 1080p AHD camera kit.

Problem: The kiosk required discreet security camera views of touch areas and bill acceptors, but the design team rejected visible domes or large bezels.

Solution: The 6×6 mm camera was mounted behind tinted acrylic with a short-focus lens; coax routed to a hidden AHD DVR for incident review.

Result: No aesthetic compromise; the compact analog HD image provided clear evidence for service disputes. Installation avoided Ethernet rework in narrow plinths.

Keywords: discreet security camera, embedded CCTV module, compact analog HD.

Lens/FOV: Choose 120° when coverage beats detail (kiosk/area awareness). For inspection points, narrower 30–60° improves pixel density on target. Maintain back focus tolerance; lock with threadlocker if vibration is present.

Illumination: For cabinets/ducts, add 850 nm IR or neutral white LED rings. AHD conveys luminance cleanly; avoid PWM strobing that can cause rolling artifacts.

Cabling: Use 75 Ω coax (RG-59 or low-loss variants) with proper BNC terminations. For 200–300 m, specify solid copper center conductor and double-braid shield. Route away from high-current bundles.

Power: Distribute 12 V locally where possible; if sharing supply rails with drives, include LC filtering. Camera draw (~50 mA) is modest, but monitors/DVRs will dictate battery sizing for mobile kits.

EMC/EMI: AHD is resilient; still, bond shields at a single-point ground to reduce loops. In TIG/MIG environments, consider ferrite cores near camera and monitor ends.

Reliability: For continuous service, secure camera PCBs with standoffs and potting where necessary. If exposure to dust/oil mist is expected, use conformal-coated assemblies or IP-rated micro-enclosures.

Searches like “factory inspection camera over coax” and “analog HD camera system for robotics” continue to rise because these constraints persist in heavy industry.

Single-cell retrofit: One mini AHD camera at the choke point; route to a nearby 7″ AHD monitor. Typical hardware + install < one day; productivity gain shows in fewer start/stop cycles.

Line-wide viewing: Multiple cameras home-run to an AHD DVR with quad split; mirror one output to a large HMI. Operators get continuous context without switching IP streams.

Mobile service kits: Camera + monitor + battery + DVR in a foam case. Ideal for QA audits and commissioning. Simple, repeatable, and field-proven.

We design and manufacture board-level AHD and USB modules for robotics, automation, energy, and kiosk OEMs. The AC-606K is our 1080P AHD camera kit optimized for indoor industrial use. Customization covers: lens FOV, cable lengths, specialized micro-housings, and matched AHD DVR/monitor bundles. Each system is soak-tested for signal integrity and thermal stability prior to shipment.

For factories and infrastructure where space is scarce and latency is non-negotiable, the 6×6 mm 1080P AHD camera kit provides a clean, rugged path to visual awareness. It brings discreet, wide-angle coverage, long-distance analog HD, and instant visualization to the exact places where engineers need it most—robot wrists, cabinets, tunnels, ducts, and kiosks.

Call to Action:

Relative Articles of production application and 6*6mm camera products

1, AC-602 6×6mm Micro AHD Camera for London Retail Security

2, mini AHD Camera: Detroit, Chicago & US City Security Solution AC-602

3, 120° 6×6mm Mini AHD Camera Module for Embedded & Industrial vision AC-602 ( NOVEL products)

4, Micro AHD Camera 1080P ideal for Covert & Industrial Vision AC-602

5, Custom 15×15mm AHD Camera for Embedded & industrial equipment AC-501