model:AC-608, 304 Stainless Steel housing, 1080P resolution, night vision with 36pcs IR light, DC 12V power

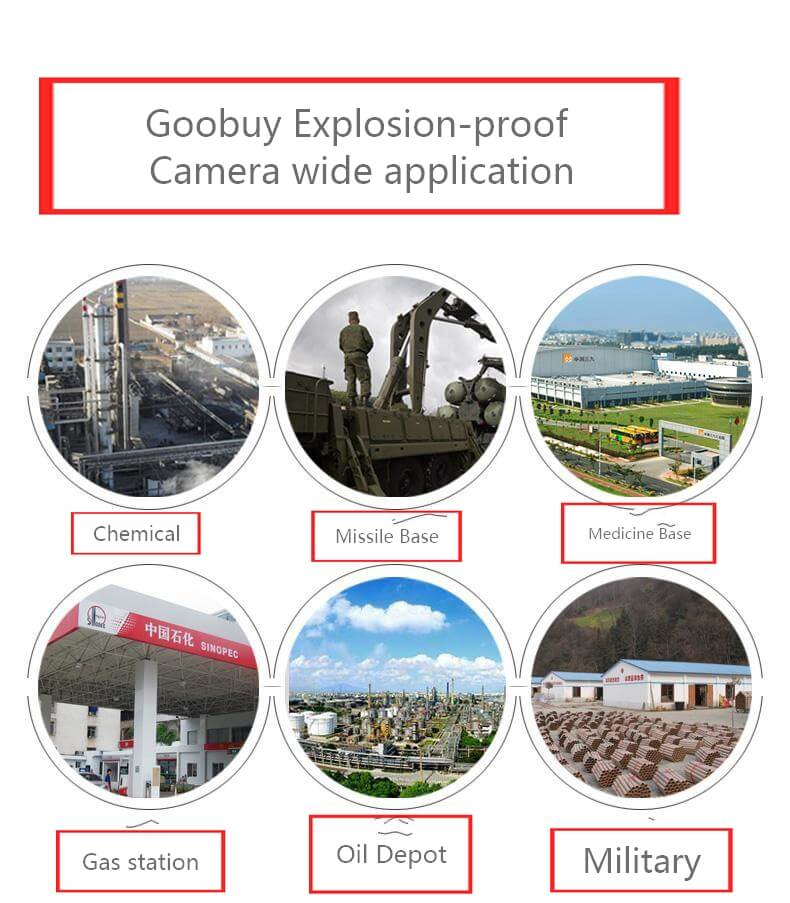

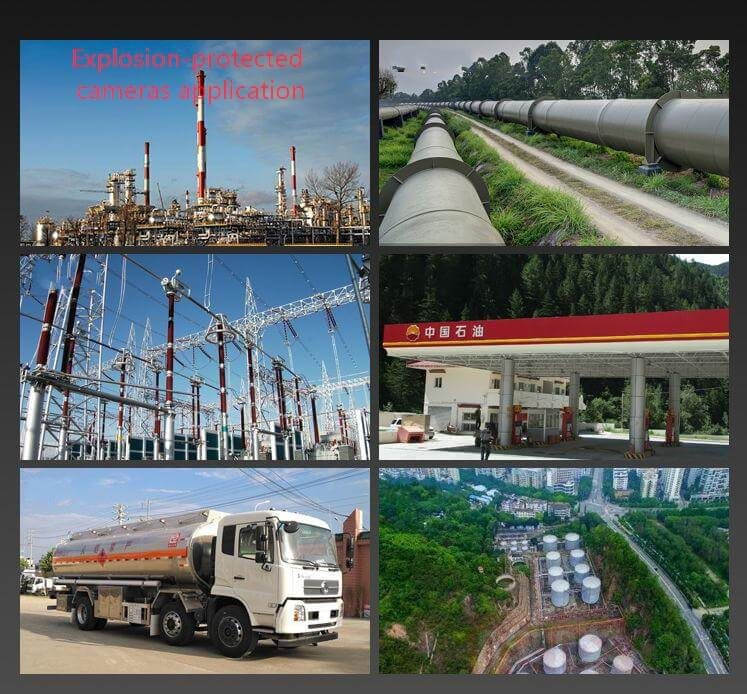

The Goobuy AC-608 is a 2MP explosion-proof AHD camera built with a 316L stainless-steel housing and IP69K protection, designed for real-time visual monitoring in hazardous industrial areas including oil & gas facilities, chemical plants, marine platforms, and dust-explosion zones.

Engineered for harsh and hazardous environments, the Goobuy AC-608 provides 1080p analog HD video with zero-latency output and a fully explosion-proof 316L stainless-steel enclosure suitable for Zone 1/2/21/22 applications. With IP69K and high-pressure wash-down resistance, corrosion-proof housing, IR night vision and optional ATEX/IECEx/CNEx certification, it enables safe and reliable visual monitoring in environments where flammable gas, chemicals, dust or high humidity are present. The AHD output integrates easily with existing coaxial DVR systems without requiring network infrastructure.

Product overview

This 316L stainless steel explosion proof camera is engineered for hazardous area CCTV where safety, durability, and compliance are mandatory. Delivering 1080p analog HD (AHD) video, the unit is ideal as a hazardous area analog HD camera 1080p solution for both new projects and retrofit systems.

Built in marine-grade 316L with IP69K hazardous location camera sealing, it withstands salt-fog, wash-down, and corrosive chemical exposure. Certified options include ATEX certified camera, IECEx Zone 1 camera, and CNEx explosion proof camera oil & gas, making it suitable for global deployments.

This 2MP AHD camera is designed for explosive and corrosive environments. Featuring a 316L stainless steel housing, IP68 waterproof rating, and real-time 1080P video, it's the ideal choice for oil & gas, chemical plants, dust-prone factories, and marine equipment.

What is a 316L Explosion-Proof AHD Camera?

The AC-608 is a specialized analog surveillance camera designed for volatile and corrosive environments. Unlike standard aluminum cameras that corrode in salt spray or spark in gas zones, this unit features a passive 316L stainless steel housing with thick, tempered glass. It prevents internal electrical sparks from igniting outside gases (Explosion-Proof) and resists acid/alkali cleaning agents (Corrosion-Proof), making it ideal for offshore rigs, chemical plants, and food processing lines.

Ideal for oil & gas, chemical, battery, and dust-sensitive industries,Rugged 2MP AHD camera with stainless steel housing, anti-corrosion and explosion-proof.

Solution: AHD analog output requires no network switch, no PoE, and no IP addressing—safe for hazardous areas.

Solution: 316L stainless steel provides resistance to acids, chlorides, solvents and marine salt fog.

Solution: Industrial-grade design operates reliably from –40°C to +70°C.

Solution: AHD transmission provides instant video with no compression delay.

Solution: IP69K enclosure protects optics and IR components during high-pressure steam cleaning.

what difficulty or troubling problems it can solve in industrial application?

Problems Solved:

Special Demands Met:

Product Specification

|

Item Name |

Technical specification |

|

Product Name |

Multifunctional FULL HD Fireproof Explosion-proof AHD camera model number: AC-607 |

|

Imaging CMOS |

½.7" color CMOS

|

|

chipset

|

F22+V30E(FH8532E)

|

|

Pixel

|

2MP |

|

Video resolution |

1920H*1080V, 1080P@25fps |

|

signal system

|

50HZ |

|

Minimum illumination

|

0Lux (night vision fill light) F 2.2

|

|

Shutter speed

|

1/50 sec-1/100000 sec

|

|

Day and night conversion mode

|

Switch IR-Cut day and night

|

|

Wide dynamic

|

Digital wide dynamic

|

|

BLC

|

automatic

|

|

Infrared distance IR

|

20 meters

|

|

Pickup audio

|

no |

|

Switch IR-Cut day and night

|

Support |

|

Signal output

|

AHD |

|

Lens feature |

Standard3.6mm 2MP 1080P |

|

temperature humidity

|

-20℃~+70℃ 0%-95%

|

|

power supply

|

12V (wide voltage 9v-15v)

|

|

waterproof level

|

IP68

|

|

Power (12v)

|

<4w (infrared start)

|

|

Net weight

|

Less than 2.0kgs |

|

product material

|

100% full Aluminum alloy, #304 stain steeless

|

|

Video output interface

|

1.0Vp-p composite video output, 75 ohm, 4pin aviation cable

|

|

Product Size |

107*98*85mm

|

The CNEx explosion proof camera oil & gas version is deployed on wellheads, FPSOs, and refineries, ensuring compliance and reliable monitoring under high-risk conditions.

As a hazardous area CCTV camera, this solution supports 24/7 monitoring in grain mills, flour plants, and lithium facilities, reducing ignition risks while maintaining visibility.

The 316L explosion proof camera marine salt fog design resists corrosion from seawater and heavy wash-down, making it ideal for ports, desalination plants, and offshore platforms.

The IP69K hazardous location camera survives high-pressure, high-temperature cleaning, critical in hygiene-sensitive production areas.

Integration-Focused FAQ

FAQ 1 — Can the Goobuy AC-608 camera be deployed in ATEX Zone 1 or Zone 2?

Yes. Optional certified versions are available for ATEX/IECEx/CNEx Zone 1/2 (gas) and Zone 21/22 (dust). Certification documents can be provided for system approval.

FAQ 2 — How does the AHD output integrate with an existing coaxial CCTV system?

The camera connects directly to any AHD/DVR recorder via standard coax (75Ω). No IP configuration, network switches or PoE injectors are required—ideal for hazardous areas where network devices are restricted.

FAQ 3 — What is the expected lifetime of the 316L housing in offshore or chemical environments?

316L stainless steel provides superior corrosion resistance to seawater, salt-fog, chlorine, acids and industrial chemicals. In marine or chemical plants, the housing typically lasts 8–15 years depending on environmental severity.

FAQ 4 — Can the Goobuy AC-608 camera withstand high-pressure wash-downs or steam jet cleaning?

Yes. The IP69K rating ensures resistance to pressurized steam (80–100 bar) and hot water cleaning commonly used in food, chemical and marine facilities.

FAQ 5 — What are the installation requirements for grounding and explosion-proof compliance?

For ATEX/IECEx areas, the housing must be grounded using the provided stainless-steel grounding point, and installation must follow certified explosion-proof conduit or cable gland procedures to maintain enclosure integrity.

FAQ 6 — How does the Goobuy AC-608 camera perform in low-light and dust-heavy conditions?

The integrated IR LEDs (20–30m) and IR-cut filter provide stable imaging in dark, dusty or smoke-prone areas. The AHD signal maintains clarity even when airborne dust reduces visibility.

FAQ7: Is this Goobuy AC-608 camera compliant with explosion-proof certifications?

Yes, optional models meet ATEX/IECEx standards. Inquire for documentation.

FAQ8: Is it suitable for marine deployment?

Yes, this is a 316L explosion proof camera marine salt fog solution with proven corrosion resistance.

Relative technical Articles and application

1, Explosion-Proof AHD Cameras for Industry

2, Novel wateproof AHD camera kit