Embedded vision systems are becoming the backbone of modern industry—from robotics and factory automation to security and medical equipment. Engineers and product managers in the US and Europe are increasingly faced with a critical question: Which camera module format delivers the best balance of performance, cost, and integration—USB, HDMI, or AHD?

This article provides a detailed technical comparison, integrates Google CPC high-value keywords, and highlights why engineers often refer to these modules as Board Camera Modules, Machine Vision Cameras, or Embedded Camera Boards in their daily work.

USB camera modules remain the most versatile option for embedded vision systems.

In automated inspection lines, USB 3.0 modules reduced detection time by 30% compared to legacy analog cameras.

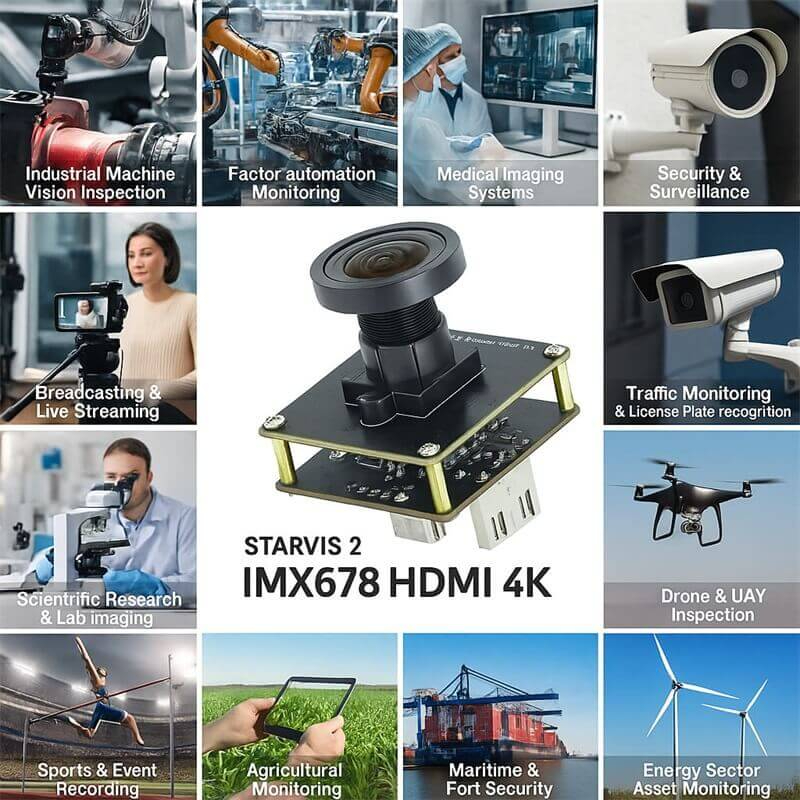

HDMI camera modules are increasingly chosen for real-time applications, especially where video needs to be displayed instantly on external monitors.

In real-world testing, HDMI modules enabled operators to identify defects in automotive assembly 40% faster compared to PC-processed video feeds.

Analog High Definition (AHD) camera modules are still widely used in embedded and industrial environments where reliability and distance are priorities.

In logistics depots, AHD modules reduced downtime by 25% due to their ability to maintain signal stability over extended distances.

|

Feature / Metric |

USB Camera Module |

HDMI Camera Module |

AHD Camera Module |

|

Image Quality |

Up to 12MP / 4K HDR |

Up to 4K HDR (Sony STARVIS) |

Up to 1080p |

|

Latency |

Medium (PC processed) |

Ultra Low Latency (<50ms) |

Low, but analog transmission |

|

Integration |

Easy (PC, AI boards) |

Monitor-based / direct output |

DVR/NVR based |

|

Transmission Distance |

Limited to 3-5m (USB 3.0 cables) |

10-15m HDMI cable |

Up to 500m coaxial cable |

|

Cost Efficiency |

Medium |

Higher (due to components) |

Low / most affordable |

|

Best For |

AI vision, robotics, inspection |

Real-time monitoring, medical use |

Security, long-distance monitoring |

For 2025, industrial engineers and developers are expected to blend USB and HDMI modules in advanced systems, while still relying on AHD for cost-effective security solutions.

By understanding strengths and limitations, companies can maximize ROI and accelerate time-to-market in embedded vision projects.