It’s the final week before project delivery. The robot cell is on the client's production floor in Silicon Valley, but it’s repeatedly failing the pick & place task. The robot arm is flawless, the PLC logic is perfect. The final diagnosis? The vision system on the end-of-arm tooling can't handle the complex shadows cast by the gripper itself when approaching a reflective PCB.

Every system integrator has faced a nightmare scenario caused by one tiny, overlooked component: the "eye" of the robot.

This article is not a product catalog. It's a strategic framework for you, the integrator, to make the right vision decisions from day one. It’s a playbook to de-risk your projects, ensure successful delivery, and protect your profit margins.

For any vision-guided robotics (VGR) project, the first decision is your integration philosophy. Do you opt for an expensive, all-in-one smart camera, or do you choose a more flexible, component-level approach?

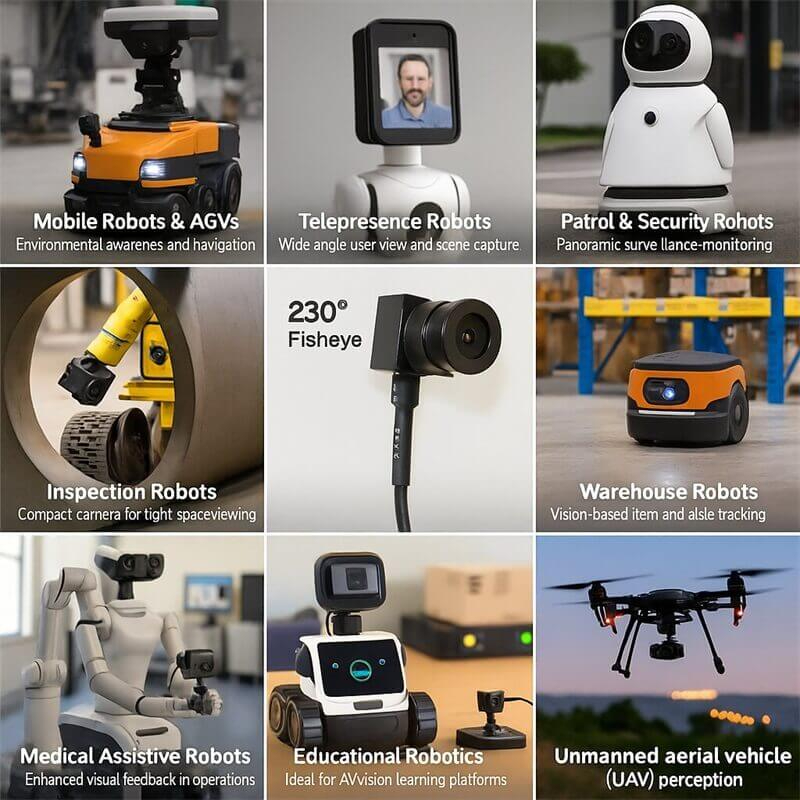

While smart cameras offer simplicity, they often come with a high price tag, larger footprint, and limited flexibility. For a high-level integrator whose value lies in creating truly custom automation solutions, integrating a board level camera for robotics offers unparalleled advantages. It allows you to choose the exact sensor, lens, and form factor your specific application demands, giving you a significant competitive edge and greater control over your project's performance and budget.

The laws of physics are unforgiving in robotics: every gram of weight and every millimeter of space on the end-of-arm tooling (EOAT) directly impacts the robot's speed, acceleration, and precision. This is where the game is won or lost in high-precision applications.

Case Study: Electronics Assembly in San Jose, CA

A leading Bay Area system integrator we worked with was tasked with developing a robotic cell for a major consumer electronics manufacturer. The project involved a robotic pick & place system for assembling micro-components onto a densely packed PCB. The robot’s gripper needed an integrated vision system for final alignment, but the space available was less than a square inch.

A standard industrial camera was out of the question due to its size and weight, which would have severely limited the robot’s agility. Their solution was to integrate our 15*15mm micro USB camera module. Its miniature footprint allowed it to be embedded directly into the custom gripper design without compromising the robot's performance, providing the high-resolution imaging needed for a mission-critical task.

The controlled lighting of your workshop is not the reality of your client’s factory floor. Complex, high-contrast lighting is one of the top reasons vision projects fail.

In the San Jose case study, the robotic cell was situated in an area with variable overhead lighting, and the reflective surface of the PCBs created unpredictable glares. The autofocus capability of our 15*15mm micro USB camera was crucial. It ensured the image remained sharp regardless of minor variations in the gripper's distance to the board. Furthermore, the high-performance 2MP sensor provided a clean signal, enabling their vision software to reliably detect fiducial marks even with inconsistent lighting, a common challenge in machine vision integration. For applications with even more extreme lighting, a WDR camera module for automation becomes essential.

The choice of interface can be the difference between a smooth integration and a month of driver-related headaches. While traditional interfaces have their place, the simplicity of USB is a massive advantage for many modern robotics applications, especially those built on PC-based or embedded controllers.

Our integrator partner in California specifically chose a USB camera module for one reason: speed of development. Their control system was based on a PC running ROS (Robot Operating System). A UVC-compliant USB camera meant it was instantly recognized by the system—no custom drivers, no complex setup. This plug-and-play capability allowed their software engineers to focus on the core vision-processing algorithms, significantly shortening the project’s development cycle.

Ultimately, the success of a complex integration project relies on the quality of your suppliers. A component is only as good as the support behind it. For an integrator, choosing a supplier means choosing a partner who understands the pressures of project-based work.

What does a true partner provide?

Making the right decisions on vision system strategy, size, performance, and interface at the beginning of a project is the most effective way to de-risk the entire process.

Is your next robotics project facing a tough vision challenge? Before you write the first line of code, we invite you to book a complimentary 15-minute "Vision Strategy Consultation." Our application engineers will help you analyze the risks and explore potential solutions—whether you end up using our products or not.