The Sony IMX678 is a next-generation STARVIS 2 sensor designed to deliver superior performance in low-light and high-dynamic-range environments. It’s optimized for industrial monitoring, machine vision, and intelligent surveillance.

Core Specifications:

|

Feature |

IMX678 |

IMX675 |

|

Technology |

STARVIS 2 |

STARVIS 2 |

|

Resolution |

8.29 MP (3840×2160, 4K) |

5 MP (2592×1944) |

|

Sensor Size |

1/1.8-inch |

1/2.8-inch |

|

Pixel Size |

2.0 µm |

2.0 µm |

|

HDR Method |

Single-Exposure HDR (artifact-free) |

DOL-HDR (multi-frame, risk of ghosting) |

|

Ideal Use |

Industrial monitoring, LPR, high-contrast robotics |

Entry-level low-light cameras, consumer security |

Key Takeaway: IMX678 delivers higher resolution and artifact-free HDR, making it better for moving objects in high contrast environments.

|

Feature |

IMX678 |

IMX415 |

|

Resolution |

8.29 MP (4K UHD) |

8.29 MP (4K UHD) |

|

Technology |

STARVIS 2 |

STARVIS |

|

HDR |

Single-Exposure HDR |

DOL-HDR (multi-frame) |

|

Motion Artifacts |

None (single frame) |

Risk of ghosting |

|

Sensitivity |

Superior low-light (improved quantum efficiency) |

Good, but older |

|

Dynamic Range |

72 dB |

~65 dB |

Key Takeaway: Both provide 4K, but IMX678 has STARVIS 2 with no HDR ghosting → ideal for license plate recognition, machine vision, and moving objects.

|

Feature |

IMX678 |

IMX307 |

|

Resolution |

8.29 MP (4K) |

2 MP (1080p) |

|

Technology |

STARVIS 2 |

STARVIS |

|

Sensor Size |

1/1.8-inch |

1/2.8-inch |

|

HDR |

Single-Exposure HDR |

No HDR |

|

Low-Light Performance |

Excellent, artifact-free |

Very good, starlight-level |

|

Target Use |

Industrial 4K machine vision, LPR, robotics |

Entry-level night vision, CCTV |

Key Takeaway: IMX307 remains a cost-effective night vision choice, but IMX678 delivers higher detail, wider dynamic range, and better industrial adaptability.

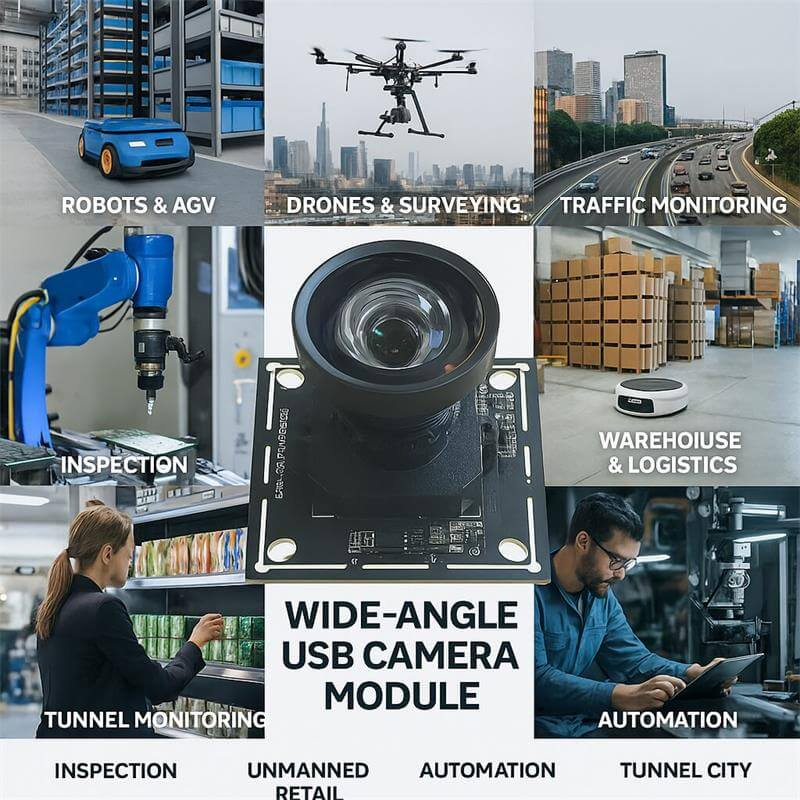

At Shenzhen Novel Electronics Limited, we integrate the Sony IMX678 into a USB 2.0 plug-and-play module with industrial-ready design:

This ensures seamless integration into machine vision systems, robotics, smart city devices, and automation equipment.

This camera module is engineered to be a versatile problem-solver, specifically for industrial and commercial applications where deploying high-resolution imaging has traditionally been limited by cost, system compatibility, or environmental challenges.

Here are the key problems it solves and the demands it meets:

1. Problem: Missed Details in Quality Control & Documentation

Lower-resolution cameras (like 1080p) fail to capture microscopic defects, fine print, or critical component details, leading to inaccurate inspections and poor-quality records.

• Solution: True 4K Resolution for Forensic Detail. With its 3840x2160 resolution, this module captures over 8 million pixels of data. This allows your system to digitally zoom in on specific areas of interest with exceptional clarity, identifying subtle flaws, verifying tiny serial numbers, or creating high-fidelity digital archives of documents and products that are simply impossible to achieve with standard HD cameras.

2. Demand: A Cost-Effective Upgrade Path for Legacy Systems

Many factories, labs, and commercial facilities run on industrial PCs and embedded systems that only have USB 2.0 ports. Upgrading this host hardware is expensive and often requires a complete system re-validation.

• Solution: Drop-in 4K Capability for Any USB 2.0 Port. This module's primary advantage is its ability to deliver high-resolution 4K video over the universal USB 2.0 interface. This allows you to instantly upgrade the vision capabilities of your existing infrastructure without the need for expensive hardware overhauls, new drivers, or complex integration, saving significant time and capital investment.

3. Problem: A "One-Size-Fits-All" Lens Limits Applications

A fixed, built-in lens means a camera is only useful for one specific distance and field of view. Different tasks often require purchasing entirely different cameras.

• Solution: Optical Versatility with an Interchangeable M12 Lens Mount. This module is not limited to a single perspective. The M12 lens mount allows you to adapt the camera to virtually any task:

o Use a wide-angle lens for general process monitoring or surveillance of a large area.

o Use a standard lens for mid-range applications like kiosk user interaction.

o Use a telephoto or macro lens to get highly magnified, close-up views for detailed component inspection on a production line. This flexibility simplifies inventory and allows one module type to serve multiple roles.

4. Demand: Reliable Imaging in Challenging, Uncontrolled Lighting

Industrial and commercial environments rarely have perfect lighting. Glare from windows, deep shadows under machinery, and sudden changes in brightness can render standard cameras useless.

• Solution: A Flagship Sensor Foundation for Superior Image Quality. At its core is the Sony IMX678 STARVIS 2 sensor, which provides an exceptional foundation for handling a wide dynamic range and performing in low light. For OEM clients, this means the module has the potential to be custom-tuned by our engineers to deliver outstanding, reliable images even in the most challenging mixed-lighting scenarios, ensuring your application gets usable data, not just a washed-out or black screen.

5. Problem: Slow Development Cycles Due to Complex Software Integration

Proprietary drivers and complex software development kits (SDKs) can delay projects by weeks or months, creating a significant drain on engineering resources.

• Solution: Rapid Prototyping with UVC Plug-and-Play Compliance. This module is fully UVC (USB Video Class) compliant. It works out-of-the-box with native drivers in nearly all modern operating systems, including Windows, Linux, and macOS. Your engineers can have a stable, high-resolution video stream running in minutes, not weeks, allowing them to dramatically reduce development overhead and focus on building your value-added application software.

The IMX678 USB Camera Module is not just a sensor—it’s a ready-to-integrate vision solution. With STARVIS 2 single-exposure HDR, 4K resolution, USB 2.0 drop-in compatibility, and optical versatility, it eliminates long-standing pain points in quality control, automation, logistics, robotics, and smart city applications.