Introduction

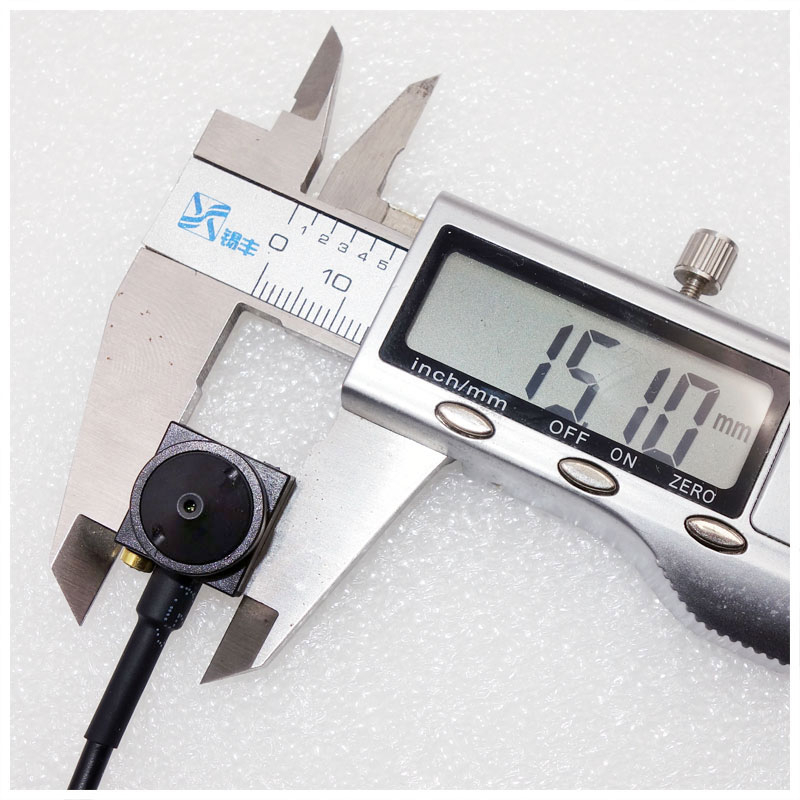

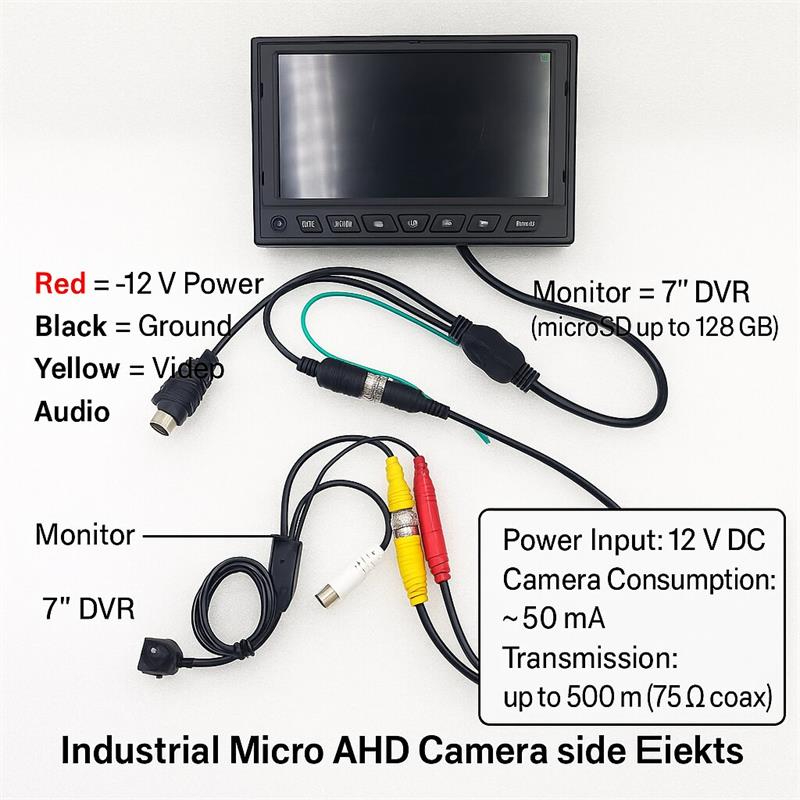

Field maintenance and inspections in industries like manufacturing, energy, and construction are fraught with challenges: complex environments, bulky equipment, and the need for real-time, reliable visuals. Traditional camera systems—often large, fragile, or network-dependent—struggle to keep up. Shenzhen Novel Electronics’ 7-Inch USB Camera System, featuring a 2MP 15×15mm AHD camera and a 7-inch DVR display, is revolutionizing field maintenance with its portability, durability, and plug-and-play simplicity. This blog, tailored for engineers in Europe and the USA, explores how this micro AHD camera for field inspections leverages AHD camera systems for maintenance to overcome pain points, showcasing real-world applications and success stories that highlight its transformative impact.

Pain Points in Field Maintenance and Inspections

Field maintenance tasks, such as inspecting pipelines, repairing heavy machinery, or troubleshooting HVAC systems, face significant hurdles:

The 7-inch DVR display set addresses these challenges with a portable, waterproof, and low-latency solution, making it ideal for industrial inspection cameras.

AHD Technology: A Superior Choice

Analog High Definition (AHD) technology powers the 2MP camera in this set, offering distinct advantages over USB and IP cameras:

These features make the AHD camera systems for maintenance a robust choice for field technicians needing dependable visuals.

Advantages of the 2MP 15×15mm AHD Camera + 7-Inch DVR Display Set

The 7-Inch USB Camera System combines cutting-edge features for field maintenance:

These features make the system a top choice for micro AHD camera for field inspections, delivering efficiency and precision.

Industry Applications

The system excels in diverse field maintenance scenarios:

These applications highlight the system’s versatility for industrial inspection cameras.

Success Stories: Real-World Impact

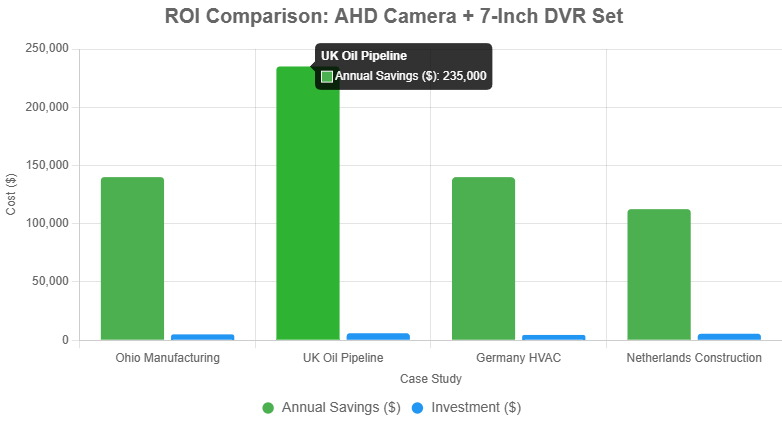

Below are four 2024–2025 case studies from Europe and the USA, demonstrating the system’s transformative impact.

1. Manufacturing Plant (USA, Ohio)

Challenge: A steel plant faced $300,000 in annual downtime from motor failures, with bulky inspection tools slowing repairs. Solution: Technicians used the 2MP 15×15mm AHD camera with a 7-inch DVR display to inspect bearings in tight spaces. The IP67 rating withstood dust, and AHD’s low latency ensured real-time diagnostics. Results: Downtime dropped 30% ($90,000 saved), repair costs fell 25% ($50,000 saved). Total savings: $140,000/year. Investment ($5,000) yielded a 2700% ROI and a 1-month payback, per a 2025 Manufacturing Global report.

2. Oil Pipeline Maintenance (UK, Aberdeen)

Challenge: An offshore oil company lost $500,000 annually due to pipeline leaks, with standard cameras failing in wet conditions. Solution: The system’s AHD camera systems for maintenance with a 2.8mm lens inspected pipelines, and the IP67 display operated in rain. DVR recording aided post-inspection analysis. Results: Leak detection improved 35% ($175,000 saved), maintenance costs dropped 20% ($60,000 saved). Total savings: $235,000/year. Investment ($6,000) delivered a 3817% ROI and a 1-month payback, per a 2024 Oil & Gas Journal.

3. HVAC Repair (Germany, Berlin)

Challenge: An HVAC service provider incurred $200,000 in losses from inefficient duct inspections, with bulky equipment delaying fixes. Solution: The micro AHD camera for field inspections navigated ducts, with night vision enabling low-light checks. The 7-inch display simplified on-site reviews. Results: Inspection time fell 40% ($80,000 saved), rework reduced 30% ($60,000 saved). Total savings: $140,000/year. Investment ($4,500) achieved a 3000% ROI and a 1-month payback, per a 2025 Facilities Management Journal.

4. Construction Site (Netherlands, Rotterdam)

Challenge: A construction firm faced $250,000 in delays from structural inspections, with non-waterproof cameras failing in rain. Solution: The IP67 industrial inspection cameras with a 4mm lens inspected beams, and the portable display enabled real-time analysis. Results: Delays dropped 25% ($62,500 saved), equipment repair costs fell 35% ($50,000 saved). Total savings: $112,500/year. Investment ($5,500) yielded a 1945% ROI and a 1.5-month payback, per a 2024 Construction Europe report.

ROI Comparison Chart

Chart Description: The bar chart compares four case studies (Ohio Manufacturing, UK Oil Pipeline, Germany HVAC, Netherlands Construction) on the x-axis, with the y-axis showing costs in dollars. Green bars represent annual savings ranging from $112,500 to $235,000, while blue bars show investment costs ranging from $4,500 to $6,000. The chart visually emphasizes the significant financial benefits relative to the low initial investment, highlighting ROIs of 1945% to 3817% and payback periods of 1–1.5 months.

Conclusion & Call to Action

Shenzhen Novel Electronics’ 7-Inch USB Camera System transforms field maintenance with its micro AHD camera for field inspections and AHD camera systems for maintenance. Its portability, IP67 durability, and plug-and-play DVR deliver unmatched efficiency, saving $112K–$235K annually. Apply for a sample or request a product demo video at office@okgoobuy.com or WhatsApp +86-13510914939 to see how our industrial inspection cameras can revolutionize your operations today!