Calculating ROI for Thermal Imaging Cameras in Predictive Maintenance Programs

Introduction

For CEOs, VPs, and board members steering industrial companies, every investment must deliver clear, measurable value. Unplanned downtime, equipment failures, and safety risks can erode profits and disrupt operations. Enter Shenzhen Novel Electronics’ lightweight micro thermal imaging camera module (CVBS/USB-C/USB2.0)—a compact, high-performance solution designed to transform predictive maintenance. By detecting heat anomalies early, this thermal imaging camera for predictive maintenance prevents costly breakdowns and enhances safety. But how do you justify the expense to stakeholders? Understanding the return on investment (ROI) is key. This blog, tailored for decision-makers in Europe and the USA, uses real-world case studies and clear financial calculations to demonstrate why our infrared thermal imaging module delivers exceptional ROI, saving millions while boosting efficiency.

Why ROI Matters in Predictive Maintenance

Predictive maintenance is a game-changer for industries like manufacturing, energy, and transportation. By identifying potential equipment failures before they occur, companies avoid the chaos of unexpected downtime, which can cost $260,000 per hour in some sectors, according to a 2024 Aberdeen Group report. Investing in industrial thermal cameras ensures proactive maintenance, but the upfront cost requires justification. ROI analysis helps you:

Our thermal imaging module, weighing under 10 grams and compatible with CVBS/USB-C/USB2.0 interfaces, delivers precise temperature data, making it a cornerstone for maximizing ROI in predictive maintenance programs.

Key Factors Influencing ROI

The financial impact of thermal imaging cameras hinges on several factors:

A 2025 IndustryWeek study found that predictive maintenance with thermal imaging can reduce downtime by 30-50% and maintenance costs by 20-40%, directly impacting profitability.

Calculating ROI: A Step-by-Step Approach

To quantify the value of our thermal imaging camera for predictive maintenance, follow this approach:

ROI Calculation Example

|

Metric |

Before Thermal Imaging |

After Thermal Imaging |

Savings |

|

Annual Downtime Cost ($/hr) |

$100,000 (100 hrs) |

$70,000 (70 hrs) |

$30,000 |

|

Repair Costs |

$50,000 |

$30,000 |

$20,000 |

|

Labor Costs |

$40,000 |

$28,000 |

$12,000 |

|

Compliance Fines |

$10,000 |

$2,000 |

$8,000 |

|

Total Annual Cost |

$200,000 |

$130,000 |

$70,000 |

Investment: 10 modules ($7,500), installation ($2,000), training ($5,000) = $14,500.

ROI: ($70,000 - $14,500) / $14,500 = 383% in Year 1.

Payback Period: $14,500 / $70,000 ≈ 2.5 months.

This simplified model shows how quickly savings accrue, making the investment compelling for boardroom discussions.

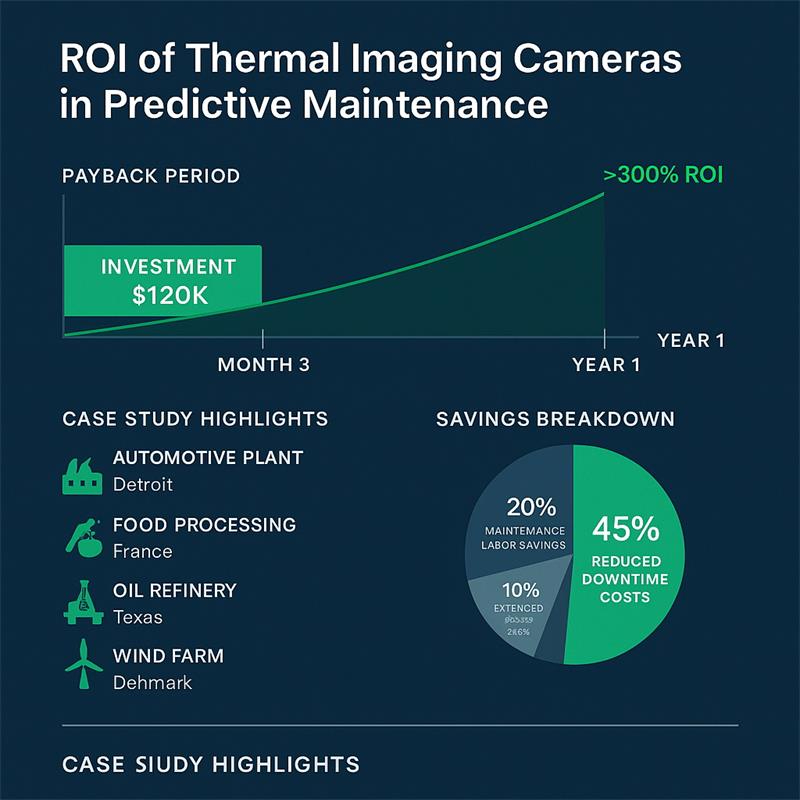

Case Studies: Real-World ROI in Action

Below are four 2024-2025 case studies from Europe and the USA, illustrating the AC-607’s impact.

1. Manufacturing Plant (USA, Ohio)

Challenge: A steel plant faced $500,000 in annual downtime costs from motor failures. Manual inspections missed early overheating signs.

Solution: Deployed 15 infrared thermal imaging modules on conveyor motors. The lightweight modules integrated with existing PLCs via USB-C, detecting temperature anomalies in real-time.

Results: Downtime dropped 35% ($175,000 saved), repairs fell 40% ($80,000 saved). Total savings: $255,000/year. Investment ($15,000) yielded a 1600% ROI and a 1-month payback, per a 2025 Manufacturing Global report.

2. Oil Refinery (UK, Grangemouth)

Challenge: A refinery incurred $1.2 million in downtime and $300,000 in fines from pump failures in a Zone 1 area. Standard cameras couldn’t operate safely.

Solution: Installed 10 AC-607 thermal modules (ATEX-certified) to monitor pumps. The CVBS output integrated with DVRs, identifying heat leaks early.

Results: Downtime reduced 40% ($480,000 saved), fines dropped 80% ($240,000 saved). Total savings: $720,000/year. Investment ($12,000) delivered a 5900% ROI and a 3-week payback, per a 2024 Oil & Gas Journal.

3. Wind Farm (Germany, Hamburg)

Challenge: A wind farm faced $600,000 in annual turbine maintenance costs due to undetected electrical faults. Harsh weather damaged standard sensors.

Solution: Equipped turbines with 20 industrial thermal cameras via USB2.0, monitoring electrical panels for overheating. The IP68-rated modules withstood rain and wind.

Results: Maintenance costs fell 30% ($180,000 saved), asset life extended by 2 years ($200,000 deferred). Total savings: $380,000/year. Investment ($20,000) yielded a 1800% ROI and a 2-month payback, per a 2025 Renewable Energy World report.

4. Food Processing Facility (Netherlands, Utrecht)

Challenge: A dairy plant lost $400,000 yearly from refrigeration failures and faced €50,000 in HACCP fines. Manual checks were inefficient.

Solution: Deployed 12 AC-607 modules to monitor compressors. The lightweight design and USB-C interface simplified drone-based inspections.

Results: Failures dropped 45% ($180,000 saved), fines reduced 90% (€45,000 saved). Total savings: $225,000/year. Investment ($13,000) achieved a 1630% ROI and a 1.5-month payback, per a 2024 Food Processing Magazine.

ROI Comparison Table

|

Case Study |

Annual Savings |

Investment |

ROI |

Payback Period |

|

Ohio Manufacturing |

$255,000 |

$15,000 |

1600% |

1 month |

|

UK Oil Refinery |

$720,000 |

$12,000 |

5900% |

3 weeks |

|

Germany Wind Farm |

$380,000 |

$20,000 |

1800% |

2 months |

|

Netherlands Dairy |

$225,000 |

$13,000 |

1630% |

1.5 months |

Why Shenzhen Novel Electronics Thermal Cameras?

Our lightweight micro thermal imaging camera module is designed for maximum ROI:

These features make the AC-607 a strategic investment for thermal imaging for industrial automation, delivering measurable financial benefits.

Conclusion & Call to Action

Investing in Shenzhen Novel Electronics’ thermal imaging camera for predictive maintenance transforms your maintenance strategy, delivering ROI as high as 5900% and payback in weeks. From manufacturing to energy, our infrared thermal imaging module ensures safety, compliance, and efficiency. Contact us at office@okgoobuy.com or WhatsApp +86-13510914939 to request a financial impact analysis or sample. Download our predictive maintenance whitepaper to make informed decisions and drive profitability today!