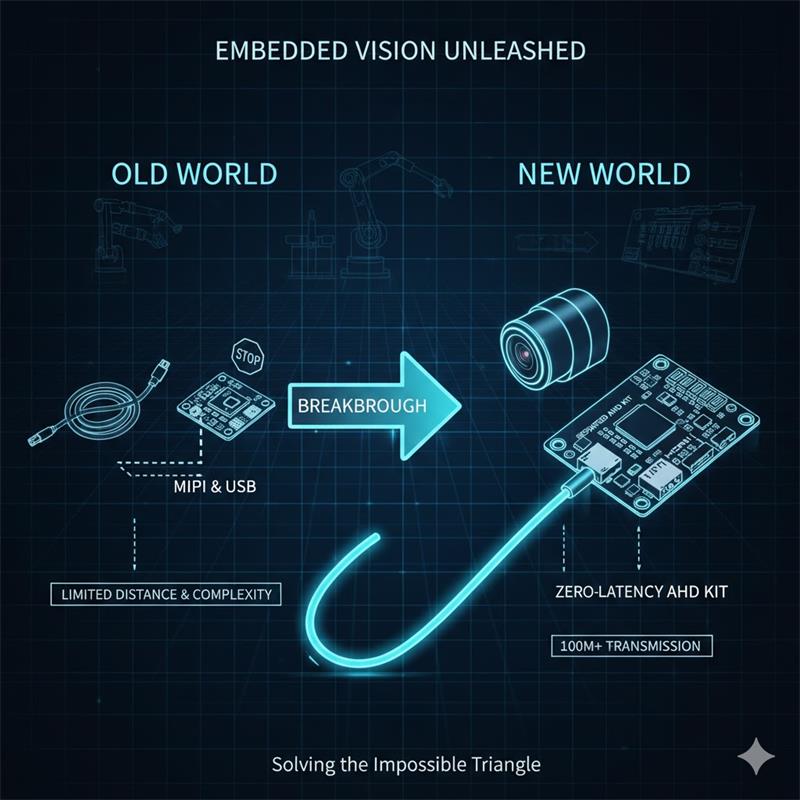

For engineers and product managers developing the next generation of robotics, medical devices, or industrial automation, designing the perfect Embedded vision system often feels like an exercise in compromise. The ideal system demands a list of conflicting features: a camera small enough for extreme space constraints, a signal robust enough to travel long distances, and video transmission that is immediate and lossless.

This challenge can be defined as the "Impossible Triangle" of embedded vision design, forcing teams to make critical trade-offs. This article will explore this dilemma and introduce a breakthrough solution that refuses to compromise: the separated AHD camera kit.

Engineers are typically forced to choose their vision architecture from three primary options, each with a significant drawback that compromises the final product's performance or the project's timeline.

MIPI CSI-2: The Challenge of Complexity and Distance The primary appeal of a MIPI-based Miniature camera module is its small footprint and high bandwidth. However, this comes at a significant engineering cost. The high-speed differential signals are notoriously sensitive to EMI and require careful PCB layout and impedance control. Cable lengths are severely limited, often to just a few centimeters, and extending them is complex and unreliable. The MIPI vs AHD for embedded vision debate often centers on this very point: MIPI's integration complexity creates significant development overhead and risk.

USB: The Challenge of Distance and Robustness The UVC (USB Video Class) standard makes USB cameras incredibly easy to integrate, offering plug-and-play simplicity. However, standard USB 2.0 cable lengths are practically limited to 5 meters, and even less in noisy industrial environments. While suitable for desktop applications, this limitation makes them a non-starter for systems requiring the sensor to be placed far from the host processor, a common requirement in large machinery or distributed systems.

IP Cameras: The Challenge of Latency IP cameras offer the benefit of long-distance transmission over standard Ethernet. However, this comes with an unavoidable and often variable delay. The video must be encoded on the camera, transmitted over the network, and decoded by the host. This process introduces significant latency, which is unacceptable for real-time control applications. The AHD vs IP camera latency comparison is stark: IP latency is measured in hundreds of milliseconds, while AHD latency is measured in single-digit milliseconds.

A separated AHD (Analog High Definition) camera kit is architected specifically to solve this "Impossible Triangle" by combining the best attributes of each alternative without their inherent flaws.

Advantage 1: Design Freedom - Decoupling the Lens from the Logic The system’s core innovation is its separated design. The image sensor is housed in a tiny module, sometimes as small as 8x8mm, while the main processing and I/O are on a separate board. This allows engineers to place the lens in extremely tight spaces—such as at the end-of-arm-tooling (EoAT) or behind a small aperture in a medical device—while the main board is safely located where space is less of a concern.

Advantage 2: The AHD Advantage - Robust, Long-Distance, Real-Time AHD technology transmits uncompressed, high-definition video over standard 75-ohm coaxial cable. This architecture delivers three critical benefits:

Low latency video transmission: Because the signal is analog and uncompressed, there is no encoding or decoding delay. The video feed is effectively real-time, which is essential for any application requiring human-in-the-loop control or precise machine synchronization.

A proven long distance camera cable solution: AHD signals can be reliably transmitted over hundreds of meters with no signal degradation, completely eliminating the distance limitations of MIPI and USB.

Reliable video for harsh environments: Coaxial cable provides excellent shielding against the electromagnetic interference (EMI) commonly found in factory settings, ensuring a stable and clear signal where other interfaces might fail.

Advantage 3: The All-in-One Architecture - Simplifying Your System Unlike a typical Industrial board camera that requires a host PC or single-board computer for control and recording, this kit functions as a Standalone DVR camera module. With onboard SD card recording and direct HDMI/AV outputs, it operates as a self-contained unit. This drastically simplifies the overall system architecture, reduces the bill of materials (BOM), and eliminates potential points of failure associated with a host operating system.

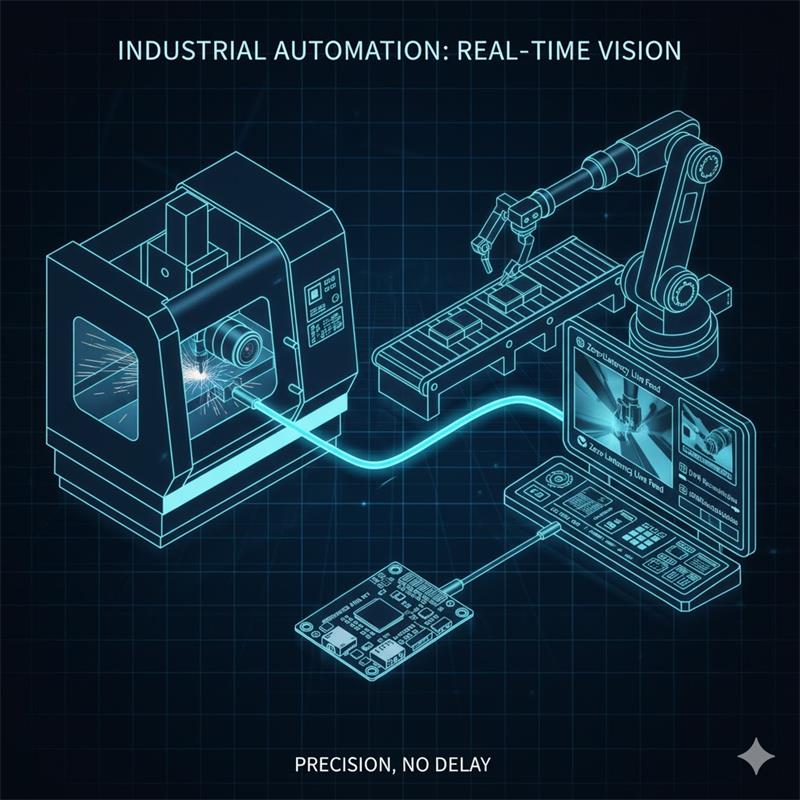

Use Case 1: Industrial Automation

Challenge: Monitoring the tool-point inside a CNC machine, requiring a small camera that can withstand a high-EMI environment and provide a zero-latency feed to the operator.

Solution: The miniature AHD lens is mounted inside the machine, with the main board outside. The operator gets a perfectly real-time view via HDMI, ensuring precise control and immediate fault detection.

Use Case 2: Medical Devices

Challenge: Integrating vision into a surgical training tool or diagnostic equipment, where real-time visual feedback is critical and space is at a premium.

Solution: The tiny, sterilizable camera head can be integrated into the tool tip, providing a lag-free image to the surgeon or technician on a medical-grade monitor, while the DVR records the entire procedure for documentation.

Beyond its standard features, this AHD kit is a flexible platform designed for customization. As an ODM (Original Design Manufacturer) solution, everything from the lens (field of view, low-light performance), cable (length, material, connector), and even firmware features can be tailored to meet the specific requirements of your project, providing a competitive edge over off-the-shelf solutions.

The era of choosing between a small camera, a long-distance camera, or a low-latency camera is over. The separated AHD kit architecture proves that it is possible to achieve all three. By breaking the "Impossible Triangle," it empowers engineers to stop making compromises and start building more capable, reliable, and innovative machines.

Have a unique challenge? Talk to our engineering team to discuss a custom solution or request an evaluation kit to see the difference for yourself.