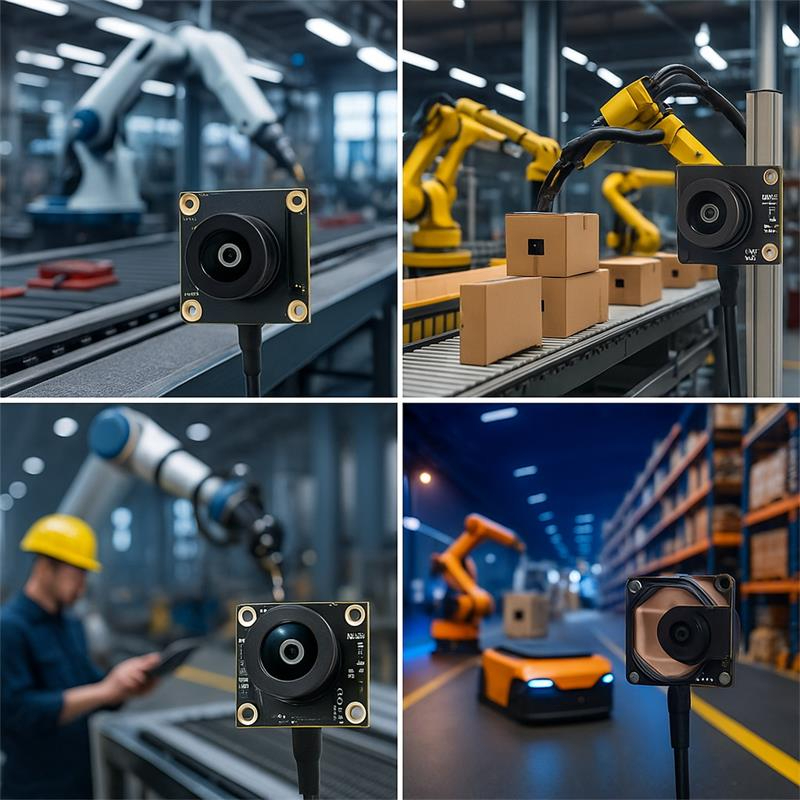

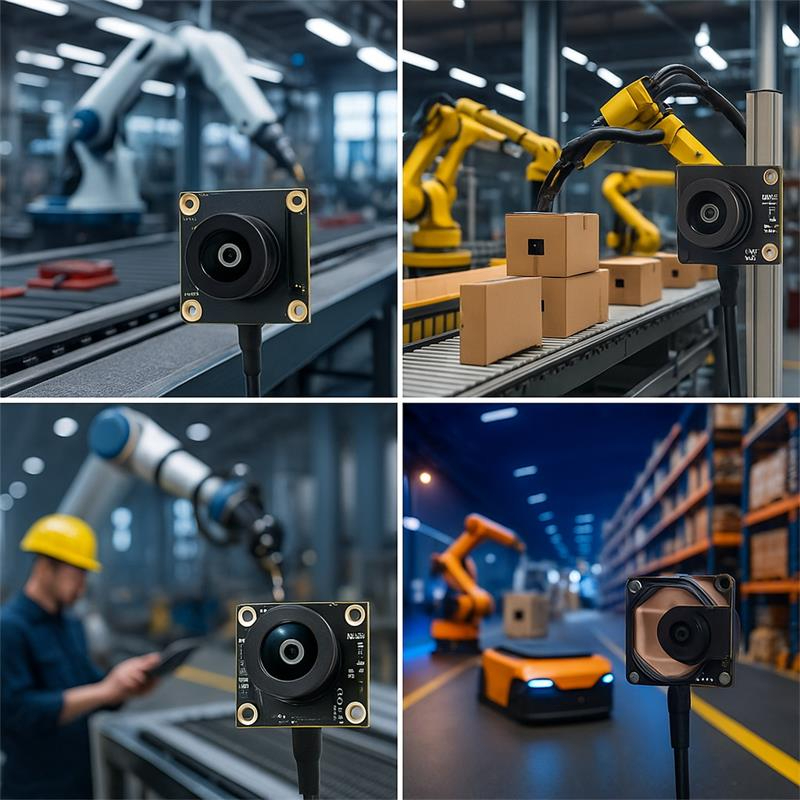

2025 Industrial Vision Trends: Miniaturized USB Cameras, High Resolution, Night Vision & Edge AI for Manufacturing

In 2025, industrial vision has moved from “seeing clearly” to “understanding, collaborating, and integrating effectively”. Under the dual pressure of cost reduction and compliance, manufacturers are investing in smaller, more powerful, and easier-to-integrate vision solutions. Miniaturized sensors, higher resolution with enhanced night vision, plug-and-play USB cameras, edge AI processing, and intelligent safety detection are the dominant trends.

This article summarizes the key technology and procurement shifts in the USA, EU/UK, Switzerland, and Russia, and provides actionable selection guidelines.

1. Miniaturization: From “Fits in Place” to “Fits Anywhere”

Key Points

- 15×15 mm micro camera modules are now the go-to choice for collaborative robots (Cobots), AMR/AGVs, compact inspection fixtures, electronic shelf labels, and portable terminals.

- Miniaturization is not just about size—it’s about reducing weight, cable complexity, and installation limitations, which lowers end-effector inertia and stabilizes cycle times.

Regional Highlights

- USA – In discrete manufacturing and 3PL logistics, AMRs often deploy multiple cameras; micro end-of-arm cameras improve flexible picking performance.

- EU/UK/Switzerland – Machine tools and medical devices require smooth, safe, and clean designs, and compact modules simplify compliance.

- Russia – Energy and heavy industry sites face housing space constraints, making small modules more cost-effective for retrofits.

Selection Checklist

- Size ≤ 15×15 mm, weight < 10 g.

- Interchangeable lens or multiple focal length options.

- EMI shielding for high electrical noise environments.

2. Higher Resolution: From “Recognition Usable” to “Measurement Reliable”

Key Points

- 2MP remains the best value for real-time tasks, but 5–12MP is gaining ground in precision inspection, metrology, and fine-grain AI classification.

- Higher resolution extends working distance and field of view, reducing the number of cameras needed.

Regional Highlights

- USA – 5–12MP for AOI, solder joint, and silkscreen inspection in electronics/semiconductors and Tier-1 automotive.

- EU/UK – High resolution plus color consistency for grading defects in food and pharmaceutical industries.

- Switzerland – Medical device and micro-assembly applications require high resolution + low distortion optics.

Selection Checklist

- ≥ 5MP (2592×1944 or higher) with low-distortion lens matched to pixel size.

- ROI cropping and resolution downscaling for frame rate control.

- Calibration and color matching for multi-camera setups.

3. Better Night Vision: From “Visible” to “Reliable in Low Light”

Key Points

- Increasing use in night shifts, dim warehouses, and outdoor energy facilities demands low-light (Starlight/Starvis) sensors and Wide Dynamic Range (WDR).

- Near-IR compatibility (850/940 nm) with low red-eye ensures safety and privacy in human-machine environments.

Regional Highlights

- USA/UK logistics & retail – Low light + moving targets demand high SNR and low motion blur.

- EU chemical/energy facilities – Strong backlight requires robust WDR.

- Russia/Northern Europe – Outdoor winter operations need ultra-low-light + IR.

Selection Checklist

- Low-light sensitivity (e.g., 0.001 lux) with adjustable gain/exposure.

- WDR ≥ 90–120 dB.

- IR-cut/IR-pass options, anti-red-eye, and noise reduction toggle.

4. Simpler Integration: Plug-and-Play USB Cameras Return to Engineering Logic

Key Points

- With mature edge computing, UVC-compliant USB cameras are preferred for driver universality, combined power/data cabling, and simpler wiring, ideal for Cobots, AMRs, industrial tablets, and embedded PCs.

- Compared to MIPI/GigE, USB offers a smoother prototype → small batch → mass production transition.

Engineering Benefits

- Weeks-to-days development cycle with Linux/Windows/ROS out-of-the-box support.

- Low replacement cost with cross-brand compatibility.

- Simplified wiring (5V power + data in one cable) reduces cable drag in joints.

Selection Checklist

- Standard UVC, supports Jetson/x86/Raspberry Pi.

- Stable 1080p@30/60fps with low packet loss.

- Cable strain relief for moving-joint applications.

5. Edge AI Enhancement: On-Site Understanding and Decision-Making

Key Points

- Vision workloads shift from cloud analysis to on-device inference for object detection, pose estimation, defect grading, and DPM/OCR reading, with latency <50–100 ms.

- Lightweight models with quantization/distillation enable these tasks on 2–10 W edge processors.

Regional Highlights

- USA – Medical device and food safety sectors emphasize traceability and explainable AI.

- EU/UK/Switzerland – Focus on privacy-first processing and local data handling.

- Russia – Energy and transport demand offline operation in disconnected environments.

Deployment Notes

- Supports online model fine-tuning and hot updates.

- API/SDK and containerized packages for field maintenance.

- Hardware/software redundancy and health monitoring (temperature, FPS, inference delay).

6. Intelligent Safety Detection: Safer Human-Robot Collaboration

Key Points

- In human-robot shared spaces, vision enables dynamic safety zones, gesture recognition, PPE compliance, and hazard detection (sparks, smoke, fluid leaks).

- Complements laser scanners with semantic-level risk detection.

Compliance Practices

- Maintain logs and event records for audits.

- Integrate with safety PLCs or robot emergency I/O for low-latency stops.

- In EU/UK, align with machine safety and data compliance standards.

7. 2025 Industrial Vision Selection Quick Guide

- Space constraints → 15×15 mm micro USB/AHD module.

- Precision needs → 5–12MP + low-distortion lens.

- Lighting conditions → Starlight + WDR + IR-ready.

- Integration speed → UVC USB for plug-and-play.

- AI requirements → Edge inference with maintainable model pipelines.

- Safety compliance → Intelligent detection + logging + emergency stop integration.

8. Popular Applications in 2025

- Cobots/AMRs – End-of-arm picking, bin picking, obstacle detection/following.

- Electronics & precision manufacturing – Solder/AOI inspection with micron-level accuracy.

- Energy & infrastructure – Low-light inspections, gauge reading, AI-based alerts.

- Medical & lab automation – Compact, quiet, cleanroom-compatible modules.

- Smart safety & compliance – PPE checks, hazard zone intrusion, pedestrian avoidance for forklifts/AGVs.

Conclusion & Action Steps

In 2025, industrial vision success depends on system-level integration:

- Miniaturization – fits anywhere, stable mounting.

- Higher resolution – precise measurement.

- Night vision + WDR – clear in all lighting.

- USB plug-and-play – quick deployment.

- Edge AI – fast on-site decisions.

- Intelligent safety – compliant and reliable.

If you are seeking rapid-deployment vision solutions for collaborative robots, AMRs, industrial inspection, or night-time monitoring, Shenzhen Novel Electronics Limited offers a full range from 15×15 mm micro USB/AHD modules to STARVIS night vision, 5–12MP high-resolution, and edge-AI-friendly interfaces, with ODM customization and rapid prototyping support.

Call to Action

- Need a sample or datasheet? Tell us your scenario and interface requirements (USB/AHD/MIPI/USB3.0).

- Want a tailored selection guide? We can create a one-page solution plan and BOM estimate based on your space, lighting, and cycle time constraints.

Make vision smaller, smarter, and more powerful—start integrating it into your equipment today.