Across modern factories, energy plants, transport hubs, and public-service spaces, surveillance and process-monitoring cameras have become essential components of safety and automation. Yet conventional CCTV systems remain bulky, highly visible, and often impossible to integrate into confined environments such as control cabinets, robotic arms, or compact autonomous systems.

Engineers and integrators now demand discreet security cameras—modules that deliver industrial-grade clarity and long-distance signal stability while remaining nearly invisible.

The 6×6 mm AHD camera (Model AC-602) from Shenzhen Novel Electronics Limited answers this challenge with an ultra-miniature footprint, 120-degree wide angle coverage, and robust analog HD (AHD) transmission over coaxial cable.

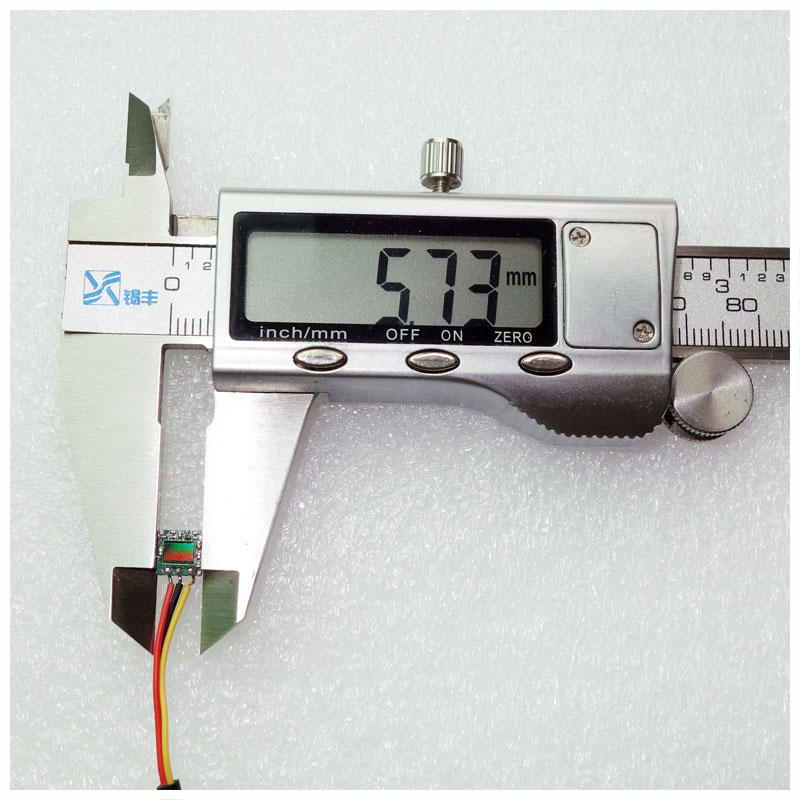

The mini AHD camera measures only 6×6 mm, yet integrates a 1/4-inch CMOS sensor, lens, and AHD encoder on a single PCB.

Its miniature form enables seamless embedding into machines, enclosures, kiosks, or mobile platforms where larger IP or USB cameras cannot fit.

A Stuttgart-based robotics manufacturer retrofitted its cobot arm with the 6×6 mm AHD camera module to monitor pick-and-place accuracy.

The tiny profile allowed the camera to sit inside the end-effector without altering weight balance. Engineers streamed real-time 720 P video through coax to an AHD DVR 30 m away, diagnosing gripper alignment issues with zero latency.

The result: a 15 % improvement in assembly yield and reduced maintenance downtime.

Field of View (FOV) defines how much a single camera can “see.”

The integrated 120-degree wide angle lens in this compact analog HD module allows a single unit to cover the area that previously required two or three fixed lenses. This reduces cost and simplifies calibration.

A maintenance firm in Michigan installed AC-602 modules inside wind turbine nacelles to record gearbox inspections.

Each 120° camera covers both the gear train and electrical panels, allowing technicians to review footage without entering confined spaces.

The wide angle reduced hardware count by 40 % while preserving clarity in dim light.

Operators reported improved safety and faster troubleshooting cycles.

Unlike IP cameras that rely on complex network protocols and switches, the AHD standard (Analog High Definition) sends HD video over standard 75 Ω coax cables up to 500 meters.

There is no packet loss, no latency, and no network configuration, making it ideal for large industrial facilities and EMI-heavy environments.

A steel plant near Dunkirk integrated dozens of these long-distance video cameras to observe rollers and belt tension zones.

Using existing coax lines, each camera transmitted real-time 720 P feeds to the central control room 500 m away.

Despite arc-welding EMI and temperature fluctuations, the signal remained stable for continuous operation over 12 months with zero data dropout.

While 4 K and 8 K resolutions dominate consumer markets, 720 P AHD strikes the right balance between detail, bandwidth, and power consumption for continuous industrial monitoring.

At 25 fps, it captures enough detail for motion analysis, object recognition, and event logging without overloading storage systems.

An Italian packaging equipment OEM deployed the 6×6 mm AHD module inside its labeling station.

720 P video streams fed a compact AI vision processor for package orientation and label verification.

The company achieved real-time fault detection with a lightweight embedded CCTV architecture and cut false rejects by 22 %.

The camera’s 12 V / 50 mA power requirement and metal-shielded design support operation from –10 to +60 °C.

Its analog transmission resists electromagnetic interference (EMI) far better than Ethernet-based IP solutions.

A Norwegian utility retrofitted its HV substations with micro AHD modules inside switchgear cabinets.

Traditional IP cameras suffered signal dropouts under EMI; the industrial surveillance module remained stable throughout load transients and fault switching.

The coax layout reused existing conduits, reducing installation time by half.

Because the PCB is only 6 × 6 mm, OEMs can embed the module into plastic or metal enclosures with minimal rework.

This “invisible integration” is essential for applications requiring covert surveillance or aesthetic uniformity.

A London-based AI retail startup embedded discreet security cameras inside its vending machines for face and motion analysis.

The micro AHD design fit behind the display panel without visible openings, preserving design aesthetics and user privacy.

720 P streams via AHD enabled real-time behavior analytics without network configuration.

The AC-602 module pairs easily with 7″ or 10″ AHD monitors to create a lightweight, battery-powered inspection tool.

Technicians can connect it directly to field DVR units for portable visual diagnostics.

A Houston-based pipeline maintenance company built custom inspection kits using the mini AHD camera module and a 7″ display.

The micro lens traversed through 2-inch pipes to inspect weld joints and corrosion.

Technicians could record HD footage onsite for immediate client review—boosting workflow efficiency and reducing downtime by 30 %.

While IP and USB vision systems offer high bit-depth and network integration, AHD maintains three distinct advantages in industrial contexts:

These attributes make compact analog HD cameras ideal for real-time diagnostics and legacy infrastructure upgrades.

With over a decade of experience in industrial camera design, Shenzhen Novel Electronics Limited supplies OEM and ODM modules for automation, robotics, and security integration.

Each AHD module undergoes environmental and signal stability testing before shipment.

Customization options include lens FOV, cable length, connectors, housing, and IP rating — ensuring compatibility with global embedded CCTV requirements.

From robotic vision to AI retail, from energy infrastructure to field inspection, the 6×6 mm 720 P AHD camera module delivers clarity, stability, and discretion in spaces where traditional cameras simply cannot go.

Its combination of micro size, wide coverage, and long-distance signal integrity redefines what engineers can achieve with analog HD technology.

contact us right now: e-mail to office@okgoobuy.com whatsapp me +86 13510914939 Call office now +86 755 29775656

Download the AHD Datasheet | Request a Custom Quote | Explore Integration Options

products links https://www.okgoobuy.com/Industrial-Embedded-AHD-Camera-module.html

Q1: From an Engineer: "How do I integrate this 6x6mm camera into our existing PLC or PC-based control system? Is it compatible with our vision software?"

A1: This is a critical integration question. This camera outputs an AHD (Analog High Definition) signal, so it cannot connect directly to a PC's USB or Ethernet port. Integration is typically handled in two ways:

For Real-Time Monitoring (by an operator): The simplest use is to connect the AHD signal directly to any AHD-compatible monitor or DVR. This provides a zero-latency live video stream, perfect for manual operations, alignment, or safety checks, and it uses zero of your main system's CPU resources.

For Data Analysis (Machine Vision): If you need to feed the image into a PC for analysis (e.g., using OpenCV or Cognex software), you will need an AHD-to-USB or AHD-to-PCIe video capture card on the PC side. While this adds a capture step, the massive benefit it provides is that you can install the camera 500 meters away or in a high-EMI environment (like next to a welder), which is something MIPI or USB cameras absolutely cannot do.

Q2: From a Product Manager: "There are many micro cameras on the market using MIPI or USB. Why should I choose AHD technology for my new product? What is its core selling point?"

A2: This is an excellent question. The core selling point of AHD is "industrial-grade signal robustness," which is the primary weakness of MIPI and USB.

MIPI Cameras: The signal is fragile, the transmission distance is extremely short (often < 30 cm), and it is highly susceptible to EMI. It's only suitable for use inside a device's chassis (like a laptop).

USB Cameras: While convenient, the distance is limited (high-quality feeds are unreliable over 5 meters), and in an industrial setting, they are prone to disconnects or packet loss from EMI.

AHD Cameras (Our Advantage):

Zero Latency: It's an analog signal, providing "what you see is what you get" feedback, which is critical for robotic control.

Long Distance: Easily transmit 300-500 meters over standard coax cable.

EMI-Resistant: The signal is exceptionally stable, perfect for factory floors filled with motors, VFDs, and high-voltage equipment.

If you are developing a product that will be installed in large machinery, requires long cable runs, or must operate in a harsh electrical environment, AHD is the differentiating feature that ensures your product's stability.

Q3: From a CTO: "What is the long-term reliability of this 6x6mm module? How does it perform in harsh, 24/7 industrial environments with heat and vibration?"

A3: Reliability is our core design consideration. The AC-602 module is built specifically for industrial environments:

Wide Temperature Range: It is rated to operate from -10°C to +60°C, ensuring stability in most enclosed cabinets or factory floors.

Signal Integrity: The AHD technology is inherently less prone to "packet loss" or "blue screens" than digital signals (IP/USB). Under vibration or momentary interference, the signal might flicker but will instantly recover. It does not need to buffer or re-handshake like an IP camera, which prevents the loss of critical frames.

Simplified Architecture: Our solution (Camera -> Coax -> DVR/Monitor) is a closed-loop hardware system. It does not depend on the client's complex IT network or switches. This simple architecture is extremely stable, easy to maintain, and will not be affected by network storms or IT firmware updates, ensuring true 24/7 uptime.

Q4: From an Engineer: "Is 720P resolution outdated in 2025? Is it high-enough resolution for defect detection or barcode reading?"

A4: This is a very practical question. In industrial applications, higher resolution is not always better; "appropriate" resolution is better. 720P (1 Megapixel) is more than sufficient for many monitoring and detection tasks:

For Monitoring: As shown in the case studies, 720P provides ample clarity for observing if a robotic gripper has engaged a part or if materials are jammed on a conveyor. The data footprint is also small and easy to store.

For Detection: Whether it is "enough" depends on your Field of View (FOV) and Working Distance. For close-range tasks (like reading a label or QR code in Case 4's packaging line), 720P is more than enough.

The Real Advantage: The primary benefit of choosing 720P (over 4K) is its excellent performance in very low light and its compatibility with highly cost-effective AHD DVR systems. If you do require 4K resolution, we would recommend you evaluate our other models (like the AC-606K). But for the "invisible" monitoring and diagnostic applications in this article, 720P is the optimal balance of cost and performance.

useful relative articles and 6*6mm micro AHD camera product links

1, AC-602 6×6mm Micro AHD Camera for London Retail Security

2, Innovating USA Security: Micro AHD Cameras in Chicago & LA AC-602

3, 120° 6×6mm Mini AHD Camera Module for Embedded & Industrial vision AC-602 ( Novel Products)

4, SONY Micro AHD Camera + DVR Sets for Field Maintenance

5, 1080P Micro AHD Camera Kit for Industrial Monitoring ( Novel products)

6, 15*15mm Micro AHD Kit: Houston & Orlando Security Solutions

7, NOVEL Micro AHD Camera apply For USA Machine Vision and Embedded Vision