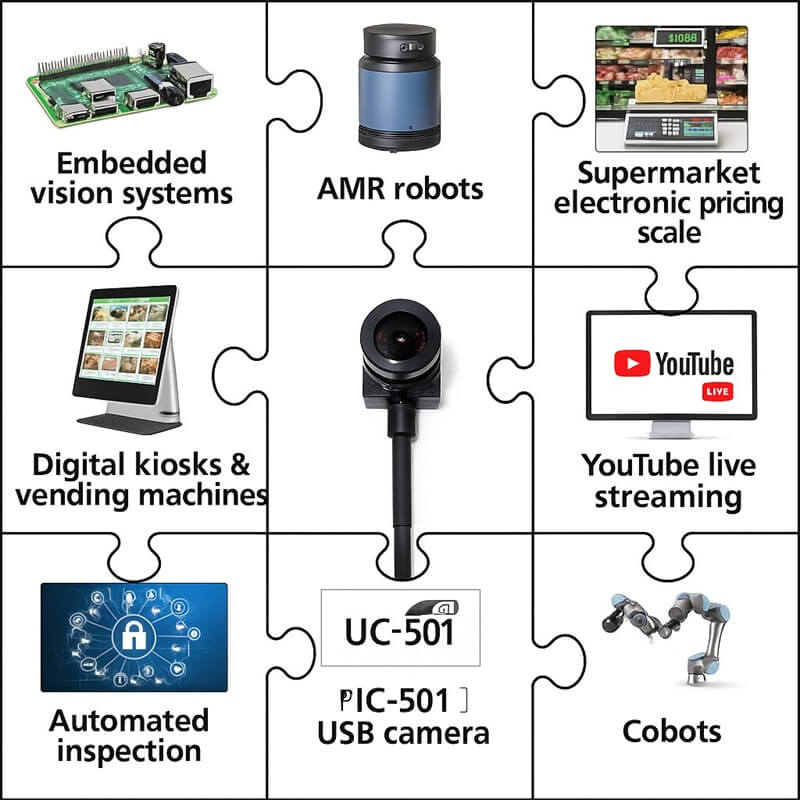

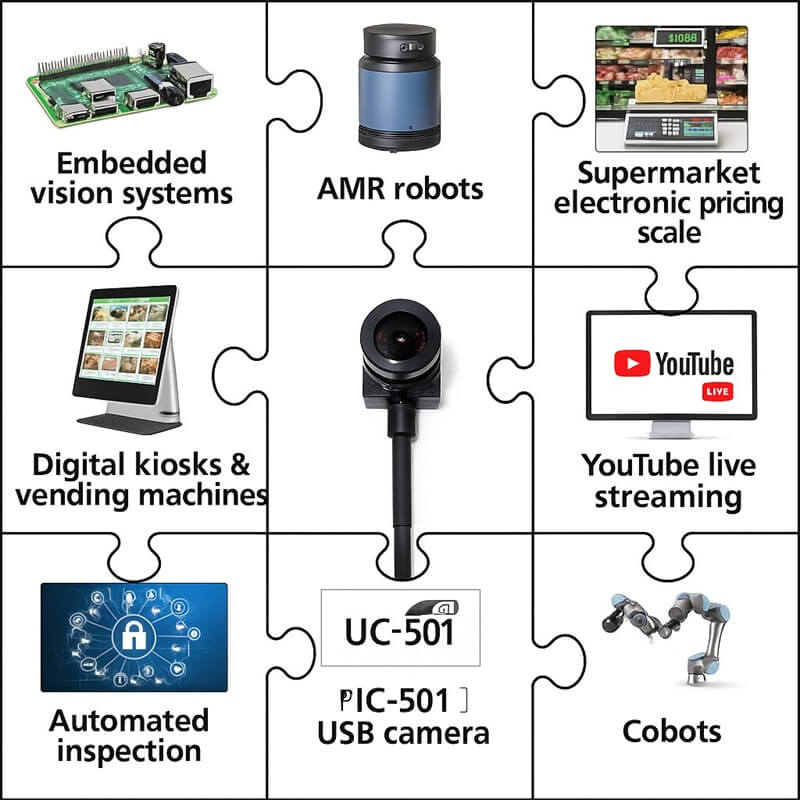

Choosing Between 2MP and 5MP Autofocus 15×15 mm USB Cameras for Robotics & Embedded Vision

In robotics, drones, and embedded vision systems, camera choice is more than a matter of resolution — it’s a decision that impacts cost, performance, latency, integration complexity, and long-term scalability.

Two of the most commonly evaluated modules in compact embedded vision designs are:

- 2MP 15×15 mm Micro USB Camera (Fixed focus)

- 5MP Autofocus 15×15 mm USB Camera

Both share an ultra-compact footprint ideal for space-constrained designs, but they differ in resolution, optics, focusing method, processing demands, and price. This blog provides a side-by-side analysis with real-world robotics applications so you can choose the right fit for your project.

1. Key Technical Differences

|

Feature

|

2MP Micro USB (Fixed Focus)

|

5MP Autofocus USB

|

|

Sensor Resolution

|

1920 × 1080 (Full HD)

|

2592 × 1944 (5MP)

|

|

Pixel Size

|

Larger (~3.0 μm)

|

Smaller (~1.4 μm)

|

|

Lens

|

Fixed focus

|

Autofocus (motor-driven or VCM)

|

|

Typical Latency

|

Lower (<50 ms at 30 fps)

|

Slightly higher (<70 ms at 30 fps)

|

|

Power Draw

|

Lower (USB 2.0 ~200–250 mA)

|

Higher (USB 2.0/3.0 ~300–350 mA)

|

|

File Size per Frame

|

~6 MB

|

~15 MB

|

|

Integration Complexity

|

Plug-and-play

|

Plug-and-play, plus autofocus driver support

|

|

Cost

|

Lower

|

1.5×–2× higher

|

2. Cost vs. Performance Considerations

2MP Micro USB Camera

- Pros:

- Lower purchase price

- Lower bandwidth requirements (USB 2.0 compatible without compression)

- Lower processing load for embedded boards like NVIDIA Jetson Nano or Raspberry Pi

- Faster integration for fixed working distance applications

- Cons:

- Limited detail capture for small object recognition

- No dynamic focusing — optimal only for a set working distance

5MP Autofocus USB Camera

- Pros:

- Higher resolution for fine detail inspection and larger field of view cropping

- Autofocus adapts to varying object distances

- More flexibility in multi-task or multi-distance applications

- Cons:

- Slightly higher cost

- Increased processing demand for high frame rates

- Autofocus mechanism may add ~20–30 ms latency during refocus events

3. Latency & Bandwidth in Real Applications

- 2MP Fixed Focus: With smaller frame sizes, image data can travel quickly over USB 2.0 without compression. For real-time robotics navigation or collision avoidance, sub-50 ms end-to-end latency is achievable, even with embedded AI inference running concurrently.

- 5MP Autofocus: While offering more detail, the extra pixels mean higher data rates. For most industrial embedded boards, 5MP streams at 30 fps are stable, but heavy image processing (e.g., deep learning object detection) may require USB 3.0 or a dedicated GPU to maintain real-time performance.

4. Application Scenarios in Robotics, Drones & Embedded Vision

Scenario 1: Autonomous Mobile Robots (AMRs) – Indoor Logistics

- Challenge: Recognize pallet positions, read QR codes, detect obstacles in warehouses.

- Recommendation: 2MP Micro USB is sufficient for QR codes >2×2 cm and object avoidance within 1 m. Low latency ensures safe navigation in mixed human-robot environments.

- Reasoning: Warehouses typically have controlled lighting and fixed camera-to-object distances, making autofocus unnecessary.

Scenario 2: Collaborative Robots (Cobots) – Small Parts Assembly

- Challenge: Align small mechanical components or electronic parts with tolerances <0.5 mm.

- Recommendation: 5MP Autofocus USB allows capturing finer details and dynamically adjusts focus for varying part heights or conveyor-based feeding.

- Reasoning: In flexible manufacturing cells, the same Cobot may switch between tasks at different distances, making autofocus a productivity booster.

Scenario 3: Drones – Infrastructure Inspection

- Challenge: Identify cracks, rust spots, or defects on wind turbine blades or solar panels.

- Recommendation: 5MP Autofocus USB offers more detail and adaptability for changing object distances during flight.

- Reasoning: Drones require high-resolution imagery for post-flight analysis, and autofocus handles distance changes without manual lens adjustments.

Scenario 4: Embedded Vision in Industrial Kiosks

- Challenge: Perform machine vision tasks such as barcode scanning, user interaction, or component verification in self-service kiosks.

- Recommendation: 2MP Micro USB delivers fast, reliable results for medium-size barcodes and facial recognition in fixed-distance setups.

- Reasoning: The kiosk environment is stable, and the cost savings can be significant in high-volume deployments.

Scenario 5: Robot-Guided Quality Inspection

- Challenge: Detect micro-defects in automotive parts on a moving line.

- Recommendation: 5MP Autofocus USB captures small scratches, thread alignment, or seal integrity more reliably.

- Reasoning: Increased resolution allows digital zoom without losing inspection accuracy.

5. Decision Guidelines for Engineers & Product Managers

|

Requirement

|

Recommended Model

|

|

Fixed distance, cost-sensitive, low-latency

|

2MP 15×15 mm Micro USB

|

|

Multi-distance, detail-critical inspection

|

5MP Autofocus 15×15 mm USB

|

|

High-speed navigation (AMRs, AGVs)

|

2MP Micro USB

|

|

Flexible robotic assembly tasks

|

5MP Autofocus USB

|

|

Drone inspection with variable distances

|

5MP Autofocus USB

|

|

Kiosk/terminal vision systems

|

2MP Micro USB

|

6. Conclusion

In industrial robotics, drones, and embedded vision systems, there is no universal "best" camera — only the right camera for the job.

The 2MP 15×15 mm Micro USB Camera is ideal for fixed-distance, latency-sensitive, and cost-conscious applications, while the 5MP Autofocus 15×15 mm USB Camera excels in detail-oriented, multi-distance, and inspection-critical applications.

For engineers and product managers in the U.S. and Europe, the choice often comes down to balancing detail with processing resources and matching the camera to the operational environment.

Shenzhen Novel Electronics Limited offers both solutions, along with customization options for lens type, housing, and integration support, helping you optimize performance across robotics, drones, and embedded vision projects.