Robotics project leaders in Europe and North America often face the same dilemma: off-the-shelf cameras rarely meet their robots’ needs. A standard camera may provide good resolution, but it lacks the right form factor, low-light performance, or USB interface. Designing a camera system from scratch, on the other hand, is expensive, time-consuming, and risky.

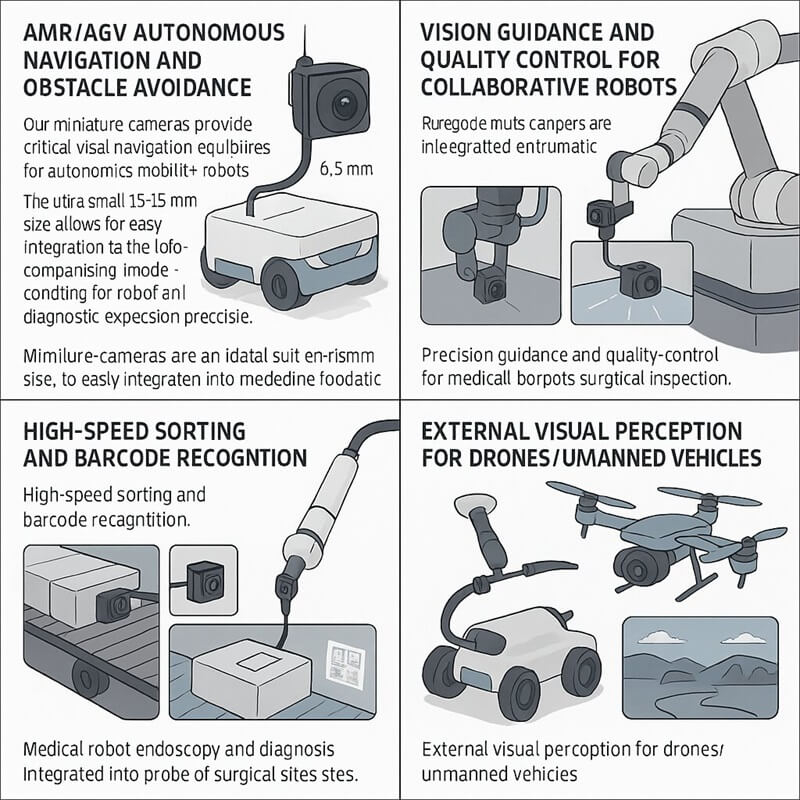

This is especially true for AMR (Autonomous Mobile Robots) and Cobots (Collaborative Robots). These systems operate in dynamic, industrial environments where cameras must be ultra-compact, reliable, and optimized for tasks like navigation, safety monitoring, and machine vision inspection.

This blog offers a clear roadmap—from choosing the right micro USB camera module to understanding the customization process—and introduces our UC-501 series (15×15mm micro USB camera, available in 2/5/8/12MP autofocus versions), already successfully deployed in U.S. and European robotics projects.

Before selecting a module, project leaders should clarify four technical pillars:

High-value keywords included: micro USB camera module, autofocus USB camera, industrial USB camera, USB3.0 camera module

Among popular STARVIS and CMOS sensors, engineers frequently compare IMX335 vs IMX307, IMX415 4K machine vision cameras, and IMX385 night vision sensors. Each has trade-offs in pixel size, low-light sensitivity, and resolution.

For robotics, the UC-501 series supports multiple sensor options (2MP to 12MP), giving project leaders flexibility to balance cost, power consumption, and vision requirements.

Our Core Recommendation:

The UC-501 Series 15×15mm Micro USB Camera:

Every customization project begins with a technical dialogue:

Our team helps translate these answers into a concrete design specification.

Instead of building from scratch, we leverage our UC-501 base platform and apply micro-customization. This reduces risk and accelerates time-to-market.

Options include:

High-value keywords included: custom USB3.0 camera module, low light USB camera, autofocus industrial USB camera

Speed matters in robotics development. Once specs are confirmed, we provide rapid sample delivery, so engineers can test vision algorithms, object detection, and navigation performance without waiting months.

Our European and U.S. partners consistently highlight that fast prototyping reduces R&D cycles by 30–40%.

After successful testing, we scale to production:

One U.S. robotics integrator faced a challenge: their AMRs needed an ultra-compact autofocus USB camera to support warehouse navigation under mixed lighting. Off-the-shelf webcams failed due to size and poor low-light sensitivity.

By integrating our UC-501 15×15mm 5MP autofocus USB3.0 camera module, the client achieved:

Today, this solution is deployed across dozens of logistics centers in the U.S.

High-value keywords included: AMR vision system, cobot vision camera, machine vision USB camera

Customizing a micro USB camera module doesn’t have to be slow or costly. By selecting the right partner and leveraging proven platforms like our UC-501 series, you can achieve tailored solutions quickly—without reinventing the wheel.