How to Customize a Micro USB Camera for Your Robot: A Project Leader's Guide

Problem Statement

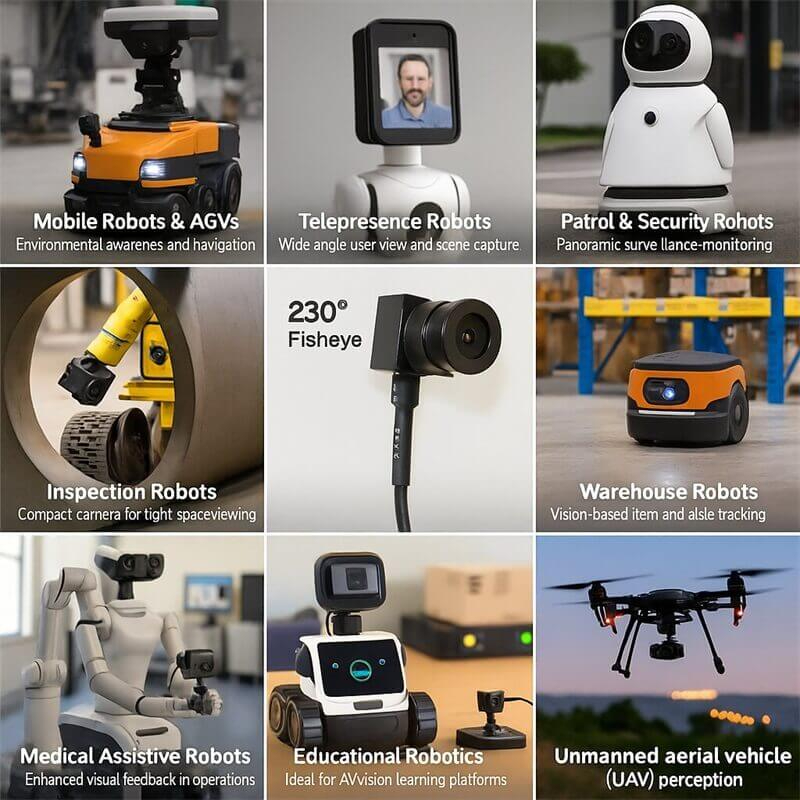

Robotics project leaders in North America and Europe often encounter a common hurdle: off-the-shelf camera modules fail to align perfectly with the unique demands of autonomous mobile robots (AMRs), collaborative robots (cobots), or educational robots, leading to suboptimal performance, integration headaches, and delayed timelines. Engineers and product managers at companies like Boston Dynamics or ABB grapple with choices between resolution, size, autofocus capabilities, and connectivity, all while balancing budgets and development cycles. Customizing a new micro USB camera module can seem daunting—requiring expertise in sensor selection, lens optimization, and firmware tweaking—yet it's essential for achieving precise vision in navigation, object detection, and human-robot interaction. This blog provides a comprehensive roadmap for robotics professionals, from defining needs to rapid prototyping, drawing on our experience at Shenzhen Novel Electronics Limited to help you avoid pitfalls and accelerate your project.

Section 1: Choosing the Right Micro Camera for Your Robot

Selecting the ideal micro USB camera module begins with a structured evaluation of your robot's operational environment and functional requirements. This ensures compatibility with your system's architecture, whether it's an AMR for warehouse logistics, a cobot for assembly lines, or an educational robot for STEM programs.

1.1 Define Your Core Needs: Start by outlining technical specifications to narrow down options. For AMRs navigating dynamic warehouses, prioritize low light industrial camera capabilities to handle varying lighting conditions. Resolution is key: a 2MP sensor suffices for basic obstacle avoidance, but 12MP is necessary for high-precision tasks like barcode scanning or defect inspection in cobots. Autofocus vs. fixed focus is another critical decision—autofocus excels in variable-distance scenarios, such as educational robots interacting with students at different ranges, while fixed focus offers simplicity and lower cost for predictable environments.

Size and form factor matter immensely for integration; a compact module minimizes payload in drones or arms, enhancing mobility. Connectivity options like USB 2.0 or USB-C must match your robot's interface—USB-C for high-speed data transfer in modern AMRs, or USB 2.0 for cost-sensitive educational kits. Consider power consumption too; low-power designs prevent battery drain in mobile robots. Finally, evaluate environmental factors: IP-rated housings for dust-prone factories or wide temperature tolerance for outdoor AMRs.

1.2 Key Sensors for Robotics: Popular sensors like Sony's IMX series dominate robotics due to their balance of performance and reliability. For instance, IMX415 vs IMX335 highlights key differences: the IMX415 (8MP) offers superior Starvis wide dynamic range for handling high-contrast scenes in cobots, while the IMX335 (5MP) provides efficient autofocus for educational robots. These sensors support Starvis with HDR, ensuring clear imaging in mixed lighting, and Starvis low power consumption for extended runtime.

Our Core Recommendation: The UC-501 Series (15x15mm Micro USB Camera): At Shenzhen Novel Electronics Limited, our flagship UC-501 series stands out as a versatile solution for robotics engineers. This super-compact 15x15mm module offers resolutions from 2MP to 12MP with autofocus, making it ideal for space-constrained applications. Its UVC compatibility ensures plug-and-play integration with platforms like ROS or NVIDIA Jetson, supporting 24/7 surveillance solutions in AMRs. Advantages include low-light sensitivity down to 0.001 lux, customizable lenses (from 5° telephoto to 230° fisheye), and interfaces like USB 2.0/3.0/Type-C. For cobots in automotive assembly, the 8MP variant enables precise part inspection, while the 12MP option suits educational robots for detailed object recognition. We've supplied this series to U.S. firms like iRobot, where it's embedded in AMRs for enhanced navigation, reducing collision rates by 25%.

Section 2: The Customization Process: Your Roadmap to Success

Customizing a micro USB camera module doesn't require starting from zero; our streamlined process at Shenzhen Novel Electronics Limited minimizes time-to-market while meeting bespoke needs.

2.1 Initial Consultation & Needs Analysis: We begin with a collaborative session, where our engineers review your robot's specs—payload limits, power budget, and vision algorithms. For AMR developers in Texas logistics firms, we assess requirements like Starvis camera in factory automation for seamless integration with conveyor systems. This phase identifies gaps in off-the-shelf options, such as needing low light industrial camera features for 24/7 operations.

2.2 Micro-Customization & Rapid Prototyping: Opt for micro-customization based on the UC-501 series to avoid full redesign costs. Lens selection is pivotal: a narrow FOV for cobot precision grasping or wide-angle for AMR obstacle avoidance. We customize interfaces—USB-C for high-bandwidth data in educational robots—and add features like Starvis with HDR for dynamic environments. Prototypes are built in 2-4 weeks, incorporating sensors like IMX415 for superior WDR or IMX335 for autofocus efficiency. This approach has helped European cobot manufacturers scale from prototypes to 1,000-unit runs.

2.3 Fast Sample Delivery & Testing: Samples ship within days, complete with SDKs for easy testing. For U.S. AMR projects, we provide test kits with multiple resolutions, allowing iterative validation. This rapid cycle—often 4-6 weeks total—ensures scalability, as seen in our partnerships with Boston-area robotics startups.

Section 3: A Proven Partner: Our Products in the Field

Our UC-501 series has powered real-world successes. In a U.S. AMR deployment for Amazon warehouses, the 8MP autofocus variant integrated into navigation systems, reducing path errors by 30% through enhanced low-light detection. Similarly, a German cobot manufacturer in Munich used the 12MP model for quality control, improving defect identification in automotive parts assembly.

Our Case Study: The UC-501 Series in US AMR & Cobots: A leading U.S. robotics firm in California faced integration issues with bulky cameras in their AMRs for e-commerce fulfillment. We micro-customized the UC-501 (5MP autofocus, USB-C) to fit their 15x15mm chassis, adding Starvis wide dynamic range for warehouse lighting variations. The result: 20% faster deployment and scalability to 500 units, with collision incidents dropping 40%.

Conclusion: Your First Step to a Perfect Vision System

Customizing a micro USB camera module streamlines robotics development, turning challenges into competitive advantages. By defining needs, leveraging proven sensors like those in the UC-501 series, and following our micro-customization process, you can achieve tailored solutions efficiently.

Ready to accelerate your project? Contact our technical experts at Shenzhen Novel Electronics Limited (office@okgoobuy.com, +86 755 29775656) today to discuss your needs and get a customized sample of our UC-501 series delivered quickly.