In industrial vision and embedded systems, engineers and developers must evaluate sensors carefully before committing to design integration. The Sony IMX415 has quickly become one of the most attractive options in the 4K segment, thanks to its combination of ultra-high resolution, STARVIS low-light sensitivity, and wide dynamic range. Yet customers frequently raise similar technical questions about its real-world performance, integration, and thermal considerations.

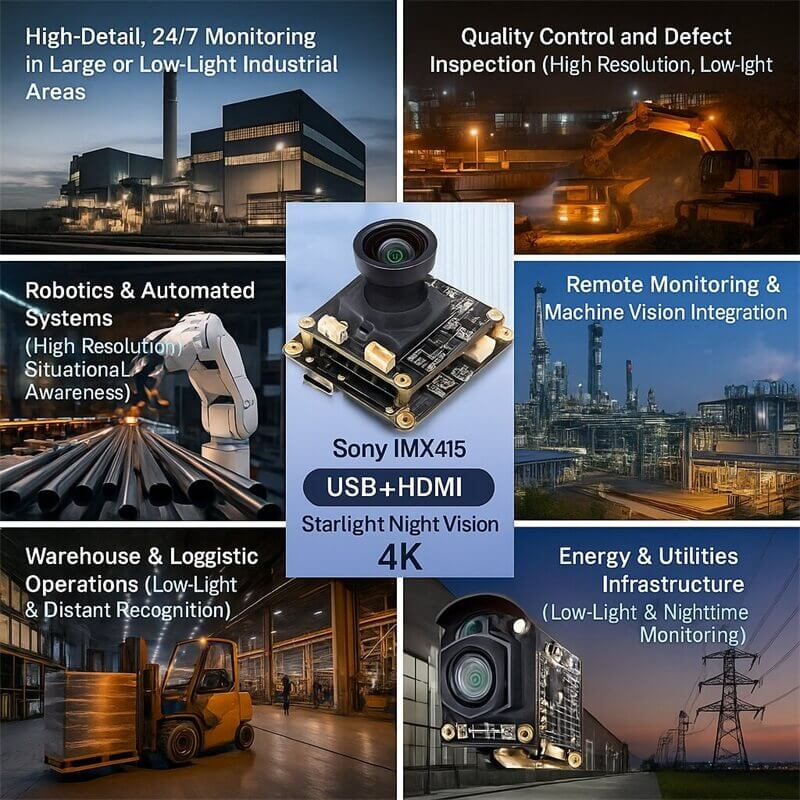

This article addresses the five most common questions from engineers in the U.S. and Europe regarding the IMX415, offering in-depth answers backed by technical insight. We also demonstrate why our 3.5mm Sony IMX415 USB+HDMI Starvis night vision 4K camera module is an excellent ready-to-use solution.

The first and most common question revolves around the core value proposition: does IMX415 deliver truly superior 4K image quality compared to other industrial sensors?

The IMX415 is a 1/2.8-inch CMOS sensor delivering a resolution of 3864 × 2192 pixels (8.4 MP) at up to 60 frames per second. This means:

In essence, the IMX415 4K industrial camera module provides image quality that rivals high-end sensors, but in a compact footprint suited for embedded devices.

While 4K resolution is the headline feature, engineers in security, robotics, and smart transportation also need to know: can IMX415 see in the dark?

Here the STARVIS architecture makes the difference. With 2.0 µm × 2.0 µm back-illuminated pixels, the IMX415 achieves a minimum illumination threshold of ~0.005 lux. This enables:

This combination of resolution plus sensitivity explains why many integrators describe IMX415 as the sweet spot between ultra-HD imaging and real-world night vision practicality.

Modern industrial vision systems often operate in complex lighting: tunnels opening into daylight, traffic intersections with headlights, or factories with both bright welding arcs and dark shadows. Engineers worry whether a 4K sensor can keep up.

The IMX415 sensor supports 120 dB wide dynamic range (WDR) with multi-exposure HDR processing. Benefits include:

Thus, as a 4K machine vision camera, IMX415 is not only about resolution, but also about maintaining data quality in tough real-world conditions.

One concern with high-resolution sensors is data throughput: more pixels mean more bandwidth, which typically translates to more power draw and heat. For embedded vision, where passive cooling is common, this is a critical design issue.

Engineers often ask: will IMX415 overheat in a compact system?

Key insights:

Overall, IMX415 power consumption is not excessive, and with standard embedded design practices, it remains stable even in fanless devices.

The final and most practical question: can developers quickly bring IMX415 into production without months of driver and SDK work?

Our customers frequently search “IMX415 driver,” “IMX415 SDK,” or “IMX415 Raspberry Pi” to gauge integration effort.

The IMX415 4K industrial camera module addresses this directly:

By using a pre-engineered IMX415 camera for 4K embedded vision, integrators avoid long debugging cycles and can focus on application-level value creation.

Based on these five answers, here’s where the IMX415 excels:

Engineers and developers ask the right questions: about image quality, low-light capability, HDR, power consumption, and integration. The Sony IMX415 delivers compelling answers in each category, making it one of the most versatile sensors for embedded vision.

Our 3.5mm Sony IMX415 USB+HDMI Starvis night vision 4K camera module is designed to help customers accelerate development: