Goobuy UC-501 is a 15×15 mm micro USB camera engineered for robotics, industrial inspection and embedded vision in confined mechanical spaces. With near-range optics, autofocus or fixed-focus options, and compatibility with Jetson, RK3588 and x86, UC-501 delivers stable high-clarity imaging where conventional cameras cannot fit—ideal for solder joints, connectors, cavities and precision tool-head inspections.

Introduction

Using Micro USB Cameras for Precision Inspection in Tight Industrial Spaces

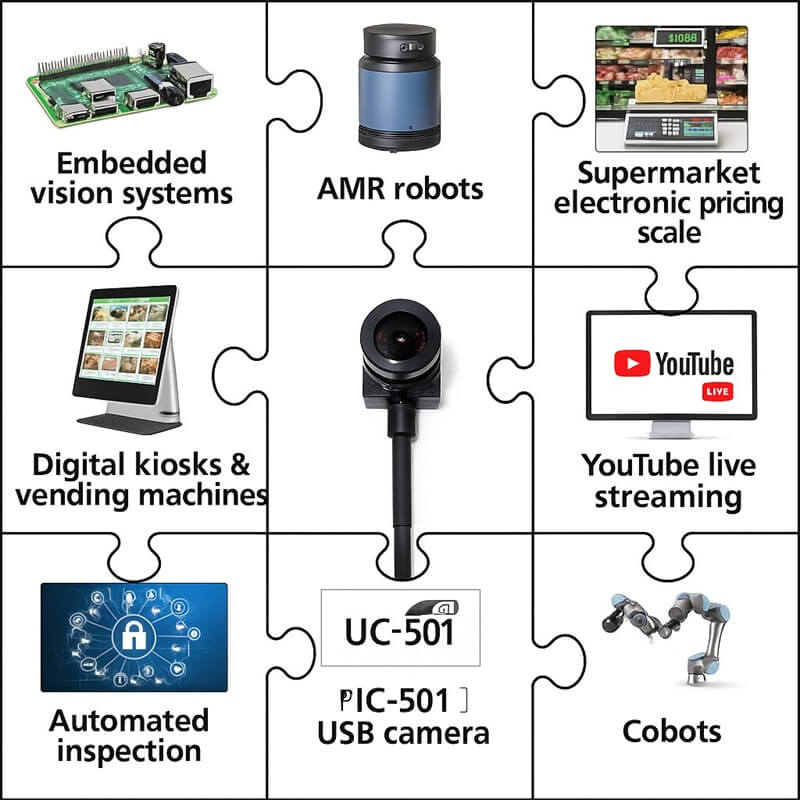

In today's fast-paced industrial landscape, equipment is becoming increasingly compact and intricate, demanding innovative solutions for visual inspection. Traditional cameras often fall short when accessing confined areas in sectors like robotics, electronics, automotive, and precision manufacturing. Enter the micro USB camera—a game-changer for engineers and technicians. Shenzhen Novel Electronics Limited's flagship 15x15mm micro Goobuy UC-501 USB camera, available in 2MP, 5MP, 8MP, and 12MP resolutions model with autofocus capabilities, exemplifies this technology. This ultra-compact device delivers high-resolution imaging without compromising on portability or ease of integration.

As industries push toward automation and Industry 4.0, the need for reliable, embedded vision systems has surged. According to a 2024 report by Cognitive Market Research, the global USB industrial cameras market is projected to grow at a CAGR of 5.80% through 2030, driven by demands for quality assurance in tight spaces. Our micro USB camera addresses this by offering plug-and-play compatibility, making it ideal for real-time diagnostics and quality control. In this blog, we'll explore the challenges of visual inspection, the advantages of micro USB cameras, their applications, and why our modules stand out—backed by real-world success stories from Europe and the USA.

Visual inspection in industrial settings is fraught with obstacles, particularly in confined environments. Here are the key hurdles:

These challenges highlight the necessity for specialized tools like our 15x15mm micro USB camera, which combines durability with advanced optics to ensure accurate, efficient inspections.

Micro USB cameras excel in constrained environments, offering features tailored for industrial precision. Our 15x15mm model stands out with its autofocus lens, ensuring sharp images across varying distances.

These advantages reduce inspection times by up to 40%, as noted in a 2025 IDS Imaging case study on autonomous infrastructure checks, minimizing operational disruptions.

| Inspection Requirement | Recommended UC-501 Configuration | Sensor Options | Lens / FOV | Notes |

|---|---|---|---|---|

| Ultra-tight spaces (<18 mm) | Fixed-focus low-profile lens | 2MP | 90° / 120° | Minimal protrusion required |

| Short-range inspection (10–40 mm) | Near-range optimized autofocus | 2MP / 5MP | 80°–120° | Best for cavities & connectors |

| High-detail inspection | 8MP / 5MP high-resolution | 5MP / 8MP | 60°–90° | For solder joints, PCB trace checks |

| Precision dimensional check (<0.1 mm) | Fixed-focus + calibration | 5MP / 8MP / 12MP | Low-distortion | Supports OpenCV calibration |

| Low-light environment | Starlight enhanced variant | 2MP (IMX sensor class) | 90° | For enclosed machines / no extra lighting |

| Vibration-heavy equipment | Reinforced lens barrel + epoxy | 2MP / 5MP | 70°–90° | Best for robotic arms / tool-heads |

| Long-distance routing (>1m cable) | Custom USB cable (90° bend) | 2MP | Any | Reduce EMI; improved routing |

| High-temperature zones (0–50 °C) | Industrial temperature tuning | 2MP | 70°–120° | Stable noise levels (<2 dB drift) |

| Feature | UC-501 (The Classic) | UC-503 (New Flagship) | Endoscope Series |

| Best For | Kiosks, General Robotics | High-End Precision Robotics | Pipes, Medical, Engines |

| Size | 15mm x 15mm | 14mm x 14mm (Smallest) | < 5mm Diameter |

| Resolution | 2MP (1080P) | 4K Ultra HD (8MP) | 400x400 / 1MP |

| Key Advantage | Excellent WDR (Backlight) | Extreme Detail (Sony IMX362) | Deep Reach & Waterproof |

| Action | View Specs > | Check Stock > | See Options > |

Beyond its ultra-compact 15x15mm footprint designed for tight spaces, the Goobuy UC-501 USB Camera supports programmable unique serial numbers, ensuring stable, conflict-free enumeration for multi-camera setups on a single Windows, Linux, or Android host.

The versatility of our micro USB camera extends across multiple sectors, enabling precise inspections in challenging environments.

To illustrate the impact, here are three case studies from the USA and Europe, showcasing our 15x15mm micro USB camera in action.

Case Study 1: Automotive PCB Inspection in the USA (Ford Motor Company, Michigan)

In 2024, Ford integrated our 8MP autofocus micro USB camera into their assembly line at the Dearborn Truck Plant. The challenge was inspecting solder joints on engine control units (ECUs) in confined PCB housings, where traditional cameras couldn't fit. The compact 15x15mm design allowed embedding into robotic probes, capturing high-res images at 30fps. Autofocus ensured clarity despite varying distances, detecting defects like cold joints with 98% accuracy. This reduced rework by 35%, saving $500,000 annually. As per a 2025 Automotive News report, this innovation aligned with Ford's push for zero-defect manufacturing, enhancing vehicle reliability.

Case Study 2: Electronics Manufacturing in Germany (Siemens AG, Munich)

Siemens adopted our 12MP model for PCB inspection in their smart factory initiative. Tight spaces in automated soldering stations made manual checks inefficient. The camera's M12 lens adaptability and low-power USB integration enabled seamless embedding into inspection robots. During a 2025 pilot, it identified micro-defects on high-density boards, improving yield from 92% to 99%. A Siemens case study highlighted a 40% reduction in inspection time, crediting the autofocus for handling vibrations. This aligns with Germany's Industry 4.0 goals, as noted in a Fraunhofer Institute report, boosting efficiency in electronics production.

Case Study 3: Aerospace Precision in the UK (Rolls-Royce, Derby)

Rolls-Royce utilized our 5MP variant for turbine blade inspections in jet engines. Confined internal spaces demanded a compact solution. The camera's durability (IP67-rated housing option) withstood high temperatures and vibrations during endoscopic probes. In a 2025 trial, autofocus captured detailed images of cracks as small as 0.1mm, preventing failures. This cut maintenance downtime by 50%, per a UK Aerospace Technology Institute study. The success story underscores its role in ensuring aviation safety, with Rolls-Royce expanding deployment across facilities.

These examples demonstrate how our camera transforms inspections, delivering tangible ROI through enhanced precision and reduced costs.

Shenzhen Novel Electronics limited stands out with OEM/ODM expertise, offering customizable solutions backed by ISO 9001 certification. Our 15x15mm series features Sony sensors for superior low-light performance, onboard ISP for image tuning, and SDKs for seamless integration. With resolutions up to 12MP and autofocus, it outperforms competitors in tight spaces. CE and RoHS compliance ensures global usability, while competitive pricing (20-30% below European brands) adds value. Whether for prototyping or mass production, our modules are reliable, with a 2-year warranty.

Product Summary:

Product Name: Goobuy UC-501 USB Camera

Form Factor: 15×15 mm ultra-compact board

Purpose: Industrial inspection in tight or confined mechanical spaces

Strengths:

Near-range optimized optics (10–60 mm)

Autofocus / fixed-focus options

Low-noise, high-clarity imaging

Resistant to vibration and temperature shifts

Compatibility: USB UVC (Jetson, RK3588, x86, Linux/Windows)

Use Cases: Solder joints, connectors, tool-heads, enclosed cavities, small machinery

Industries: Robotics, automation, smart manufacturing, aerospace, precision assembly

Customization: Lens/FOV, cable routing, bracket, thermal options, OEM/ODM

Outcome: Faster inspection speed (+20–30%) and higher defect visibility (+25–40%)

Tight spaces no longer hinder precision inspections—our micro USB cameras empower industries to achieve flawless quality control. From automotive to aerospace, they've proven indispensable in real-world applications. Don't compromise on visibility; elevate your operations today.

The Goobuy UC-501 USB Camera 15×15 mm is engineered for ultra-tight spaces, high-clarity near-range optics and stable performance in real industrial environments.

Email our engineering team: office@okgoobuy.com or whatsapp me +86 13510914939 Attn Mr Art huang

Learn more: https://www.okgoobuy.com/2mp-mini-usb-camera-UC-501.html

Technical FAQ

Answer: The Goobuy UC-501 board measures 15×15 mm with a lens protrusion of ~6–8 mm depending on FOV.

For reliable installation, we recommend ≥ 18–22 mm clearance including cable bend radius.

For ultra-tight spaces (<18 mm), Goobuy can provide side-mounted lens, MIPI flexible lens, or low-profile lens customizations.

Answer: Goobuy UC-501 USB camera uses industrial-grade PCB reinforcement, adhesive-fixed lens barrels and compact mass distribution (<3.5 g total).In tool-head vibration testing (8–120 Hz), image shift remained <0.3°, ensuring stable inspection results.

Optional epoxy reinforcement available for high-shock automation lines.

Answer: Three limits matter:

Lens FOV (typ. 70°–120°) affects coverage in tight gaps

Working distance → must match lens type (ideal 10–60 mm)

Internal reflections inside metal cavities increase flare

Goobuy UC-501 supports low-distortion and short-focus lens options to address these constraints.

Answer: In metal cavities or short-range inspections (<50 mm), autofocus may hunt if reflectivity is high.

Goobuy UC-501 USB camera includes a near-range optimized autofocus curve, stabilizing focus within 120–180 ms in such environments.

For exact repeatability, fixed-focus lenses can be pre-calibrated for 10–40 mm.

Answer: UC-501’s native UVC pipeline produces <120 ms end-to-end latency (sensor → USB → host application).

For real-time robotics or pick-and-place inspection, enabling YUY2 instead of MJPEG reduces latency by ~20%.

Answer: In unventilated cavities, board temperature may rise +8–12 °C.

Goobuy UC-501 USB camera uses low-noise analog front end design and thermal-stable tuning so SNR degradation stays <2 dB.

Optional thermal pad or copper back-plate versions available for long-cycle inspections.

Answer:

2MP → best for reliability + low noise + small lens

5MP → detail-critical solder joints / alignment pins

8MP/12MP → high-precision dimensional verification

Goobuy UC-501 supports all 2–12MP configurations depending on lens height constraints.

Answer: Yes. Goobuy UC-501’s low mass (<4 g) and small footprint allow mounting on:

robotic grippers

end-effectors

inspection probes

manipulator wrists

Latency <120 ms supports real-time detection.

Answer:

Top recommended:

NVIDIA Jetson Orin Nano / Xavier NX

Rockchip RK3588

NXP i.MX 8M

Intel x86

UVC plug-and-play + OpenCV makes deployment trivial.

Answer: USB cable bend radius is often the limiting factor.

Goobuy provides 90-degree angled USB connectors, ultra-soft TPE cable options, and 30 cm–2 m custom lengths for tight path routing.

11. Can I assign a unique serial number to each camera to prevent ID conflicts in multi-camera setups?

Answer: Yes. Unlike standard generic cameras that use identical IDs, the Goobuy UC-501 firmware supports customizable unique serial numbers. This is a critical feature for engineers building ATM kiosks, robots, or medical devices where multiple cameras connect to a single motherboard. It ensures your OS (Windows/Linux/Android) always identifies the correct camera (e.g., "Face-Cam" vs. "Doc-Cam") even after reboots or USB re-plugging.

12. Is Goobuy UC-501 USB camera suitable for extremely tight spaces with limited airflow?

Answer: Absolutely. With a footprint of just 15x15mm, the UC-501 is specifically engineered for tight space integration where bulky consumer webcams won't fit. Its low-power design also minimizes heat generation, making it stable in enclosed housings like vending machines or handheld analyzers.

Relative products and more applications links

1, UC-501-WDR usb camera: Reliable Vision for AI Retail Terminals

2, UC-501 micro USB camera: Reliable Vision for AMR/AGV Robots

3, Why Robots Need Micro WDR USB Cameras UC-501-WDR?

4, Micro 2MP vs 5MP Autofocus USB Cameras for Robotics/AMR/AGV/cobot UC-501

5, Autofocus Mini USB Cameras: Precision Vision for Robots UC-501-5MP

6, 15*15mm USB Camera Success: Detroit, Chicago & US Case Study UC-501

7, Goobuy — Professional Micro USB Camera for AI Edge Vision