In robotics, vision is not a luxury—it is a survival requirement. Robots deployed in warehouses, factories, hospitals, power plants, and open fields must interpret complex, uncontrolled lighting conditions. Yet traditional cameras, optimized for laboratory settings, often fail in the real world.

This is where micro WDR USB cameras redefine the game. They combine three unique advantages:

Wide Dynamic Range (WDR) for all-weather, all-terrain adaptability.

Miniaturization for nerve-ending perception in constrained environments.

USB/UVC plug-and-play standardization for accelerated AI integration.

Across 10 key robotic applications, these compact yet powerful modules are becoming the indispensable “eyes” of modern robots.

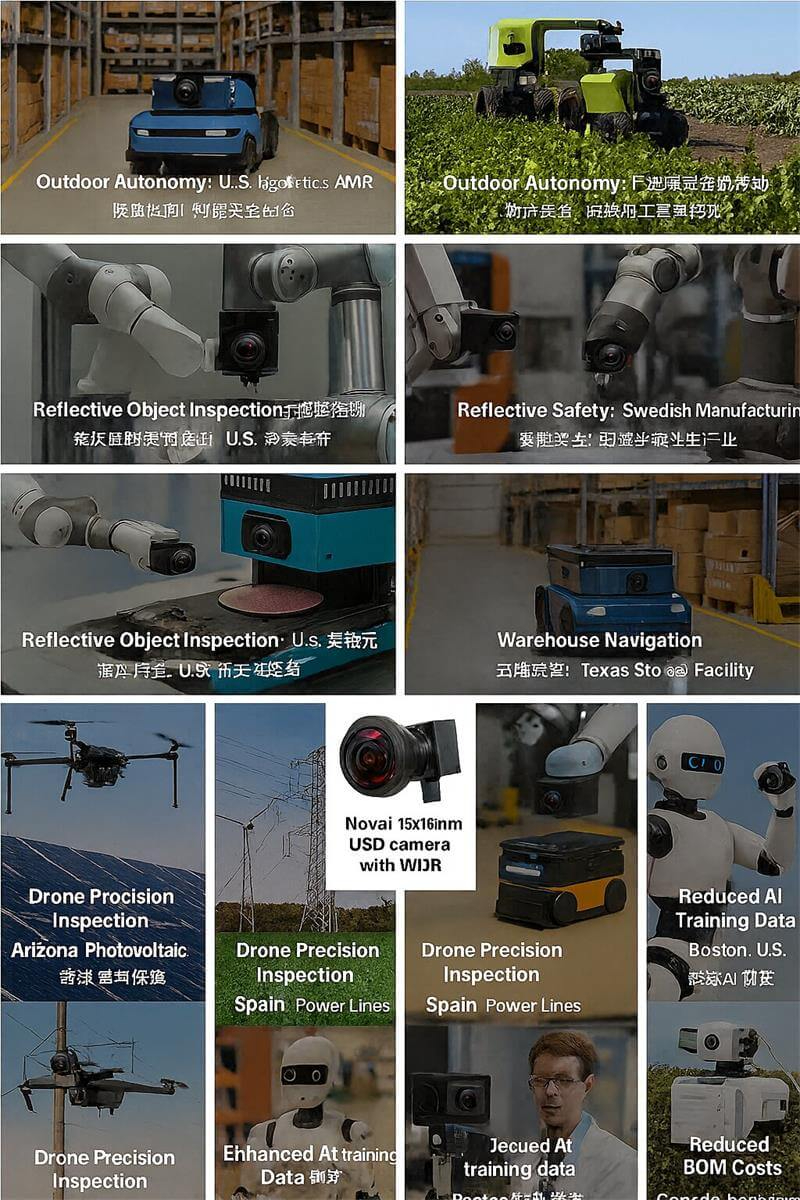

Case: U.S. Logistics AMR & France Agricultural Robot

Warehouses have bright skylights casting shadows between shelves, while agricultural robots work outdoors under shifting sunlight. A normal camera suffers “blindness” when moving from shadow to light.

A WDR camera vs normal camera comparison in a New Jersey warehouse showed AMRs with WDR USB cameras reduced navigation failures by 25%. In France, agricultural robots using WDR modules distinguished grape clusters in sun glare.

Business Value: Reliable navigation, fewer collisions, higher throughput.

Case: Germany Automotive Parts & U.S. Semiconductor

Robotic arms often face reflective surfaces—chrome car parts or semiconductor wafers. Normal cameras wash out details, leading to false inspections.

A Stuttgart automotive plant embedded a robot arm gripper camera with WDR, enabling precise scratch detection on chrome. In Ohio, semiconductor AOI robots integrated custom PCB cameras for embedded systems, eliminating false positives.

Business Value: Reduced rework, higher yield, better product quality.

Case: U.S. Automotive Cobot & Sweden Manufacturing

Cobots must safely detect human coworkers even in backlit conditions. A normal camera sees only silhouettes, risking accidents.

By deploying wide angle cameras with low distortion and WDR capability, U.S. automotive cobots avoided near-accidents, while Swedish manufacturers improved compliance with EU safety standards.

Business Value: Worker safety, legal compliance, and improved trust in cobots.

Case: Netherlands Logistics Center & Texas Facility

AMRs in Dutch distribution hubs and Texas warehouses must move seamlessly between dim aisles and bright loading docks. Normal cameras fail during transitions.

With rugged embedded cameras for robots, AMRs maintained continuous localization. U.S. integrators reported 30% fewer navigation interruptions.

Business Value: Stable operations, reduced downtime, and safer autonomous navigation.

Case: U.K. Refinery & Arizona Solar Farm

Patrol robots must detect anomalies under floodlights at night or in bright daytime glare. Standard cameras miss intruder silhouettes or equipment faults.

In a British refinery, WDR-equipped robots provided clear imaging under floodlights. In Arizona, solar farm patrol robots with outdoor robot vision solutions identified anomalies in photovoltaic panels at both dawn and noon.

Business Value: Enhanced asset security, fewer false alarms, improved ROI on robotics.

Case: Spain Powerline UAV & U.S. Wind Farm Drone

Inspection drones often face the worst contrasts: sky glare versus dark shadows on towers or blades.

Spanish UAVs with drone inspection camera payloads detected insulator cracks despite sun glare. In Colorado, wind farm drones using industrial camera modules with bulk WDR pricing improved blade defect detection by 22%.

Business Value: Lower maintenance costs, safer operations, reduced downtime.

Case: Poland Mining Robot & U.S. Tunnel Robot

Mining and tunnel robots face darkness punctuated by headlamps and welding arcs.

In Polish mines, robots with OEM WDR USB camera manufacturers’ modules preserved details in both dark tunnels and bright lights. In Nevada tunnels, robots using custom camera design services for robotics captured consistent vision despite welding flashes.

Business Value: Safer operations in hazardous conditions, reduced downtime, better resilience.

Case: Switzerland Surgical Robot & Japan Medical Robot

Operating rooms and hospitals feature mixed lighting: surgical lamps, shadows, and window glare. Normal cameras miss critical details.

Swiss surgical robots with white-label robotics vision camera modules performed more precise operations. Japanese medical robots with industrial grade USB cameras WDR enhanced their reliability in minimally invasive tasks.

Business Value: Improved surgical accuracy, reduced medical errors, stronger trust in robotic care.

Case: Boston AI Robotics Lab & France AI Laboratory

AI models require high-quality training data. Poorly exposed images degrade recognition accuracy.

In Boston, AI startups trained SLAM navigation models on WDR vs normal camera comparison datasets, cutting false negatives by 18%. French labs found WDR data accelerated AI model convergence.

Business Value: Faster model training, improved accuracy, reduced development cost.

Case: U.K. Warehouse & Canada Agricultural Robot

Without WDR, robotics integrators often add expensive external lighting.

By integrating HDR camera modules for outdoor robotics, U.K. warehouses eliminated auxiliary lights. Canadian agricultural robots reduced BOM cost by 12% with WDR modules.

Business Value: Lower cost, simpler design, lighter robots with higher energy efficiency.

Seamless adaptation from dim indoor to glaring outdoor environments.

Resistance to reflective glare from metal, welding arcs, or headlights.

Irreplaceability: Without WDR, robots cannot survive in unstructured, real-world conditions.

Cameras can be mounted at the robot arm’s gripper tip for zero-offset coaxial vision.

Capable of entering narrow gaps (engines, pipelines) for non-destructive inspection.

Irreplaceability: Micro dimensions are the physical passport to micro-level robotic operations.

Rapid development cycles: engineers focus on AI, not drivers.

Platform independence: works with PC, NVIDIA Jetson, Raspberry Pi.

Irreplaceability: Standardization accelerates large-scale deployment of AI robotics.

A micro WDR USB camera is not just another accessory—it is a capability unlocker.

It equips robots with:

The ability to see in extreme lighting (WDR).

The ability to operate in tight, critical spaces (miniaturization).

The ability to integrate quickly and cost-effectively (USB/UVC).

In essence, it becomes the robot’s eyes that adapt, penetrate, and accelerate. Without it, robots stumble in the real world; with it, they thrive across logistics, inspection, healthcare, and AI-driven industries.