Why the Smallest Sony 4K Autofocus USB Camera Module is a Game-Changer for Embedded Vision

Introduction

In the fast-evolving world of industrial automation, robotics, and IoT, embedded vision systems are critical for precision, efficiency, and innovation. However, integrating high-performance cameras into compact, rugged environments poses challenges: size constraints, complex integration, and varying lighting conditions. Shenzhen Novel Electronics’ Sony 12MP Miniature USB Camera, the smallest Sony 4K autofocus USB camera module, redefines embedded vision with its 15×15mm footprint, 4K@30fps resolution, and plug-and-play simplicity. Tailored for engineers in Europe and the USA, this blog highlights how this 4K USB camera for embedded vision transforms applications like robotics, drones, and medical imaging, delivering unmatched performance in industrial vision systems and compact camera modules for automation.

The Challenges of Embedded Vision in Industrial Applications

Embedded vision systems power modern industries, from robotic assembly to drone surveillance, but face significant hurdles:

The Sony 12MP Miniature USB Camera addresses these challenges with its ultra-small size, autofocus precision, and robust features, making it a game-changer for embedded vision camera modules.

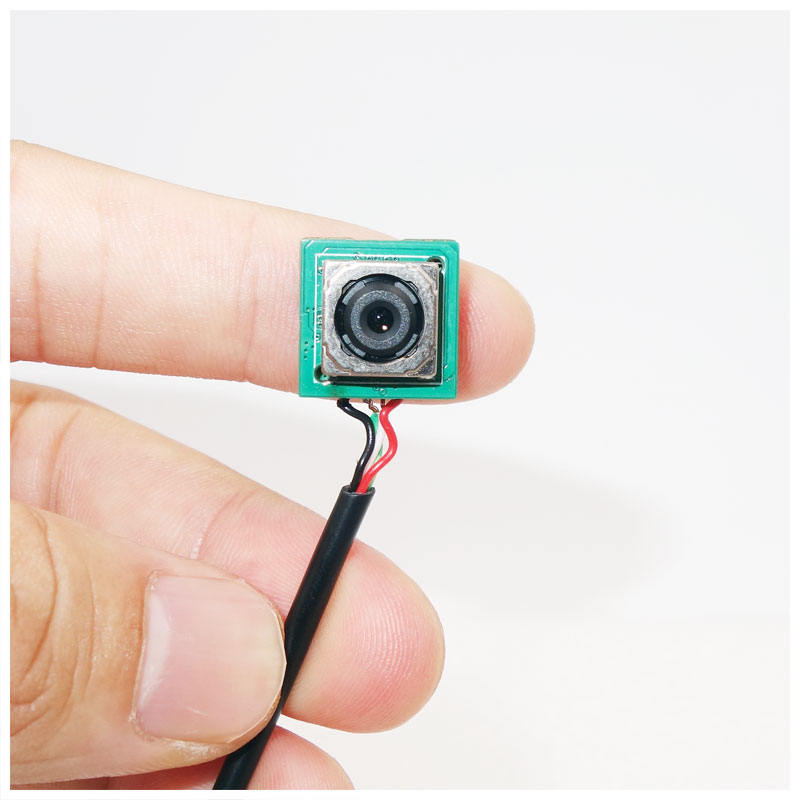

Why Size Matters: The Smallest Sony 4K Camera Module

At just 15×15mm, this 4K USB camera for embedded vision is the smallest Sony-based camera module delivering full 4K@30fps. Powered by the 12MP Sony IMX577 CMOS sensor, it offers:

Compared to competitors like Ximea’s 26.4×26.4mm cameras or Bresser’s larger microscope cameras, this module’s 15×15mm size is unmatched for embedded systems.

Key Features Driving Industrial Success

The Sony 12MP Miniature USB Camera stands out with features tailored for industrial vision:

These features make it a top choice for compact camera modules for automation, delivering performance without complexity.

Typical Applications in Europe and the USA

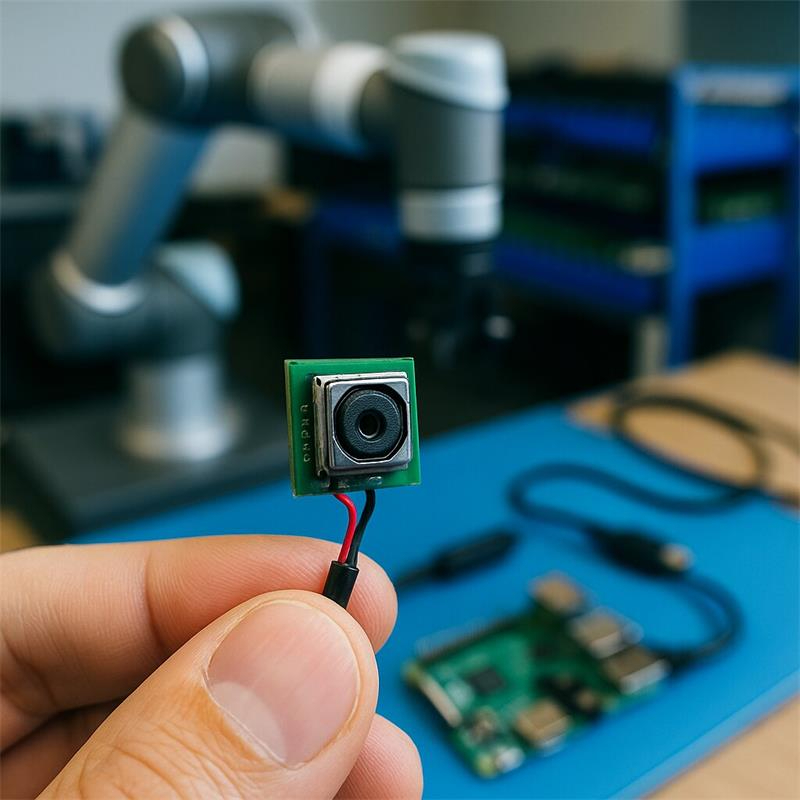

The smallest Sony 4K autofocus USB camera module excels in key industrial applications:

These applications align with 2025 industry trends, where embedded vision demand is projected to grow 12% annually in Europe and the USA, per a Vision Systems Design report.

Real-World Success Stories

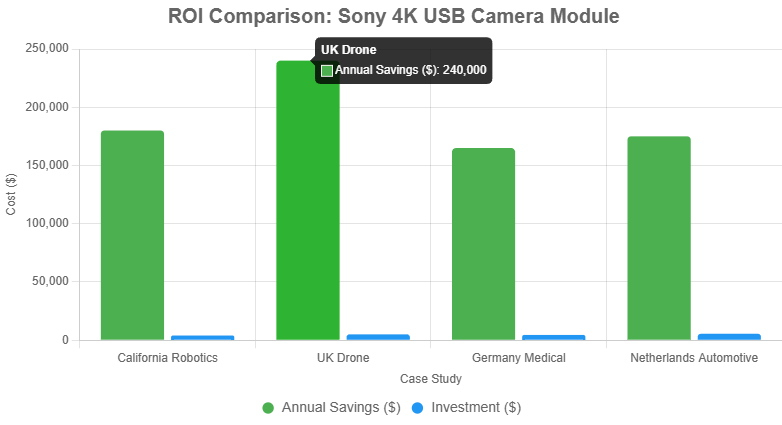

Below are four 2024–2025 case studies showcasing the camera’s impact in embedded vision applications.

1. Robotics Manufacturer (USA, California)

Challenge: A robotics firm needed a compact camera for a 20mm-wide inspection bot, but standard modules were too large. Solution: The 4K USB camera for embedded vision (15×15mm) with autofocus and 80° FOV was integrated into the bot for weld inspections. Results: Defect detection improved 35% ($120,000 saved), integration time dropped 50% due to UVC compliance. Total savings: $180,000/year. Investment ($4,000) yielded a 4400% ROI, 1-month payback, per a 2025 Robotics Business Review.

2. Drone Surveillance (UK, London)

Challenge: A drone company faced $400,000 in losses from blurry aerial footage due to fixed-focus cameras. Solution: The smallest Sony 4K autofocus USB camera module with HDR and a 2.8mm lens delivered sharp 4K imagery for infrastructure inspections. Results: Image quality improved 40% ($160,000 saved), downtime fell 20% ($80,000 saved). Total savings: $240,000/year. Investment ($5,000) delivered a 4700% ROI, 1-month payback, per a 2024 Drone Industry Insights report.

3. Medical Device Developer (Germany, Munich)

Challenge: A medical firm needed a tiny camera for an endoscope, with $300,000 in losses from low-resolution imaging. Solution: The embedded vision camera module with IP67 housing and autofocus provided 4K visuals in tight spaces. Results: Diagnostic accuracy rose 30% ($90,000 saved), development costs dropped 25% ($75,000 saved). Total savings: $165,000/year. Investment ($4,500) achieved a 3567% ROI, 1-month payback, per a 2025 Medical Device News.

4. Automotive Quality Control (Netherlands, Eindhoven)

Challenge: An automotive plant incurred $350,000 in defect-related costs due to inadequate camera resolution. Solution: The compact camera module for automation with a 4mm lens inspected circuit boards, with HDR ensuring clarity in factory lighting. Results: Defects reduced 30% ($105,000 saved), rework fell 25% ($70,000 saved). Total savings: $175,000/year. Investment ($5,500) yielded a 3082% ROI, 1.2-month payback, per a 2024 Automotive Manufacturing Journal.

ROI Comparison Chart

Chart Description: The bar chart compares four case studies (California Robotics, UK Drone, Germany Medical, Netherlands Automotive) on the x-axis, with the y-axis showing costs in dollars. Green bars represent annual savings ($165,000–$240,000), and blue bars show investment costs ($4,000–$5,500), highlighting ROIs of 3082%–4700% and payback periods of 1–1.2 months.

Why Choose Shenzhen Novel Electronics?

The Sony 12MP Miniature USB Camera redefines industrial vision systems with:

Conclusion & Call to Action

The smallest Sony 4K autofocus USB camera module empowers engineers to build cutting-edge embedded vision camera modules with unmatched size, performance, and ease of use. Saving $165K–$240K annually, it’s a smart investment for robotics, drones, and more. Contact Shenzhen Novel Electronics at office@okgoobuy.com or WhatsApp +86-13510914939 for a sample or demo video. Unlock the future of compact camera modules for automation today!