Industrial inspections and embedded vision systems demand precision, reliability, and adaptability in the tightest spaces. From pipelines to machinery diagnostics, traditional cameras often fall short due to size, durability, or integration challenges. Shenzhen Novel Electronics’ OV9734 Endoscope Camera, the smallest diameter 720P industrial endoscope, redefines these applications with its 3.9mm diameter, 720P@30fps imaging, and robust IP67 design. Tailored for engineers in Europe and the USA, this blog showcases how this industrial endoscope camera module transforms embedded vision for industrial inspection and compact endoscope for machinery diagnostics, delivering unmatched performance in confined and harsh environments.

Industrial inspections and embedded vision systems face critical challenges:

The OV9734 Endoscope Camera, with its 3.9mm diameter and advanced features, addresses these hurdles, making it a game-changer for industrial endoscope camera modules.

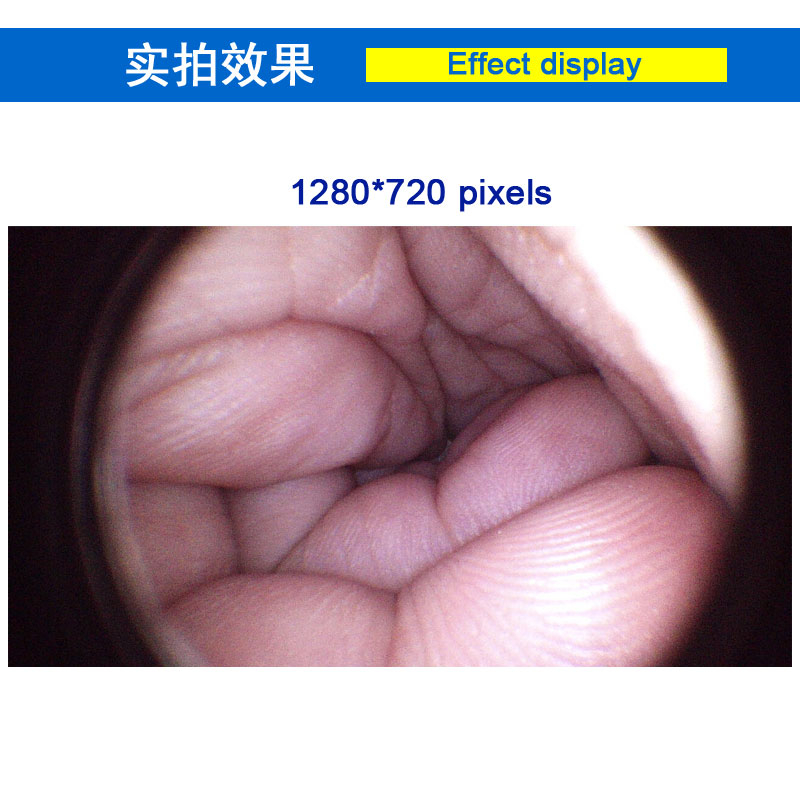

At just 3.9mm in diameter, the smallest diameter 720P industrial endoscope leverages the OmniVision OV9734 1/9" CMOS sensor to deliver:

Compared to competitors like NIDAGE’s 7.9mm borescopes or Teslong’s 5.5mm cameras, this module’s 3.9mm diameter sets a new standard for compact endoscope for machinery diagnostics.

The OV9734 Endoscope Camera is engineered for industrial and embedded vision applications:

These features make it a top choice for embedded vision for industrial inspection.

The industrial endoscope camera module excels in key industrial and medical applications:

These applications align with 2025 trends, where industrial endoscopy demand is growing 10% annually in Europe and the USA, per an Industrial Automation Journal report.

Below are four 2024–2025 case studies showcasing the camera’s impact in industrial and embedded vision applications.

Challenge: An oil company faced $500,000 in annual losses from pipeline leaks, with 5.5mm cameras unable to access 4mm pipes.

Solution: The smallest diameter 720P industrial endoscope (3.9mm) with 95° FOV and 4 LEDs inspected tight pipelines, with IP67 housing for wet conditions.

Results: Leak detection improved 40% ($200,000 saved), maintenance costs dropped 20% ($100,000 saved). Total savings: $300,000/year. Investment ($3,500) yielded a 8471% ROI, 1-month payback, per a 2025 Oil & Gas Journal.

Challenge: A semiconductor plant incurred $250,000 in defect-related costs due to bulky inspection cameras.

Solution: The industrial endoscope camera module with a 120° FOV lens inspected micro-circuits, with UVC compliance ensuring easy integration.

Results: Defect detection rose 35% ($87,500 saved), rework fell 25% ($62,500 saved). Total savings: $150,000/year. Investment ($3,000) delivered a 4900% ROI, 1-month payback, per a 2024 Electronics Manufacturing Review.

Challenge: An aerospace firm lost $350,000 annually from turbine inspection delays, with standard cameras too large for fuel lines.

Solution: The compact endoscope for machinery diagnostics with side-view lens and LEDs inspected tight components, with 720P clarity.

Results: Inspection time fell 30% ($105,000 saved), downtime reduced 20% ($70,000 saved). Total savings: $175,000/year. Investment ($4,000) achieved a 4275% ROI, 1-month payback, per a 2025 Aerospace Technology Report.

Challenge: A medical device company faced $200,000 in losses from low-resolution ENT scopes.

Solution: The embedded vision for industrial inspection module with 100° FOV and IP67 housing powered compact ENT scopes.

Results: Diagnostic accuracy improved 30% ($60,000 saved), development costs dropped 25% ($50,000 saved). Total savings: $110,000/year. Investment ($3,200) yielded a 3344% ROI, 1.1-month payback, per a 2024 Medical Device News.

Chart Description: The bar chart compares four case studies (Texas Pipeline, Germany Electronics, UK Aerospace, Netherlands Medical) on the x-axis, with the y-axis showing costs in dollars. Green bars represent annual savings ($110,000–$300,000), and blue bars show investment costs ($3,000–$4,000), highlighting ROIs of 3344%–8471% and payback periods of 1–1.1 months.

The OV9734 Endoscope Camera redefines industrial endoscope camera modules with:

The smallest diameter 720P industrial endoscope empowers engineers to tackle the toughest inspection challenges with its 3.9mm design, high-definition imaging, and robust durability. Saving $110K–$300K annually, it’s a smart choice for embedded vision for industrial inspection and compact endoscope for machinery diagnostics. Contact Shenzhen Novel Electronics at office@okgoobuy.com or WhatsApp +86-13510914939 for a sample or demo video. Transform your inspections today!